01-03-2025, 10:15 PM

Well, it is not a necessity. I was given it from my work; they did not know what to do with it.

I though at the time, it was working.

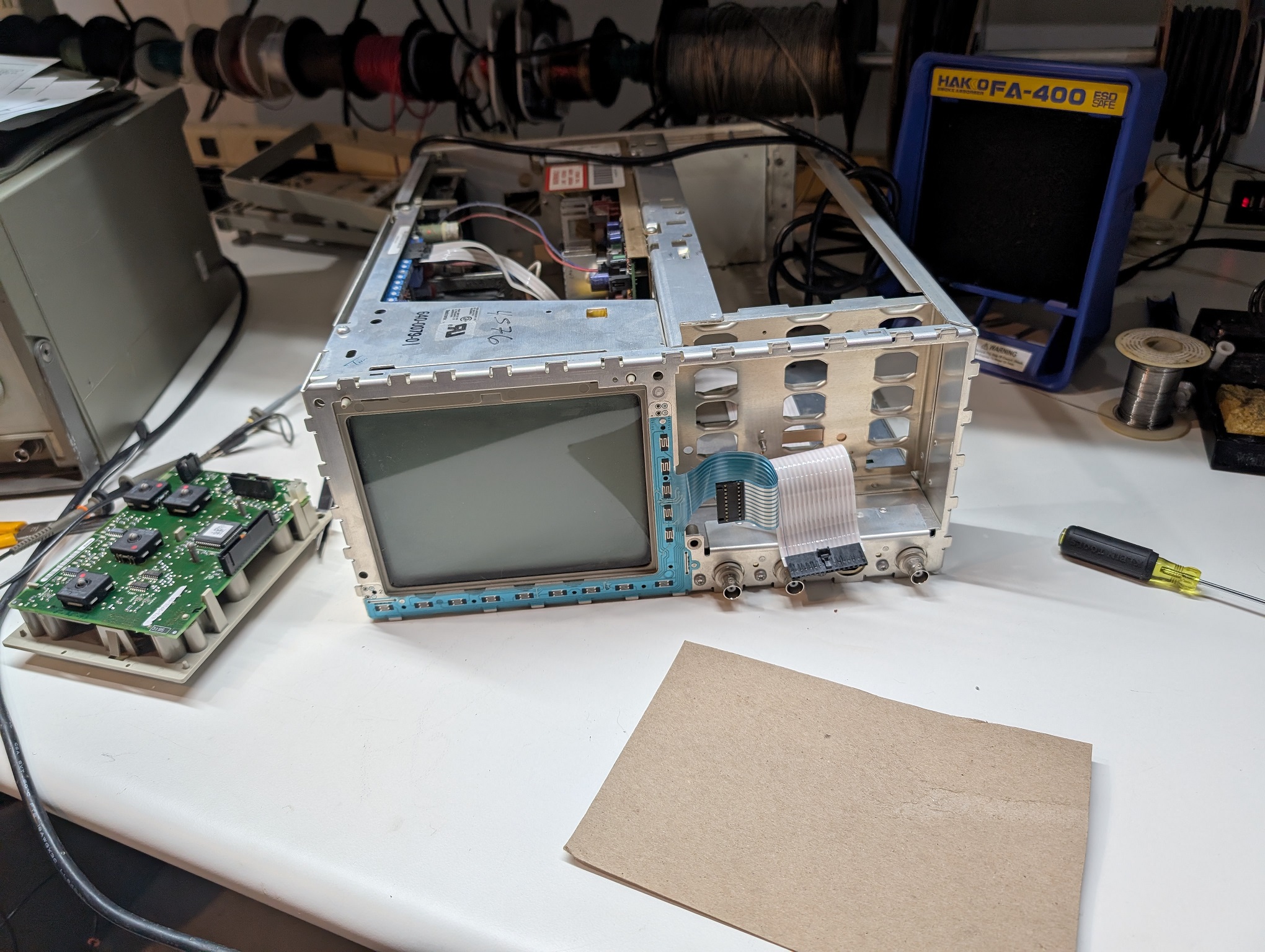

When I turned it on, the traces were there but the Front Panel buttons and controls did not work.

After many power-ups it would work, then would cease to work....after warm-up it could work for a long time and I wouldn't be able to stop it from working to troubleshoot.

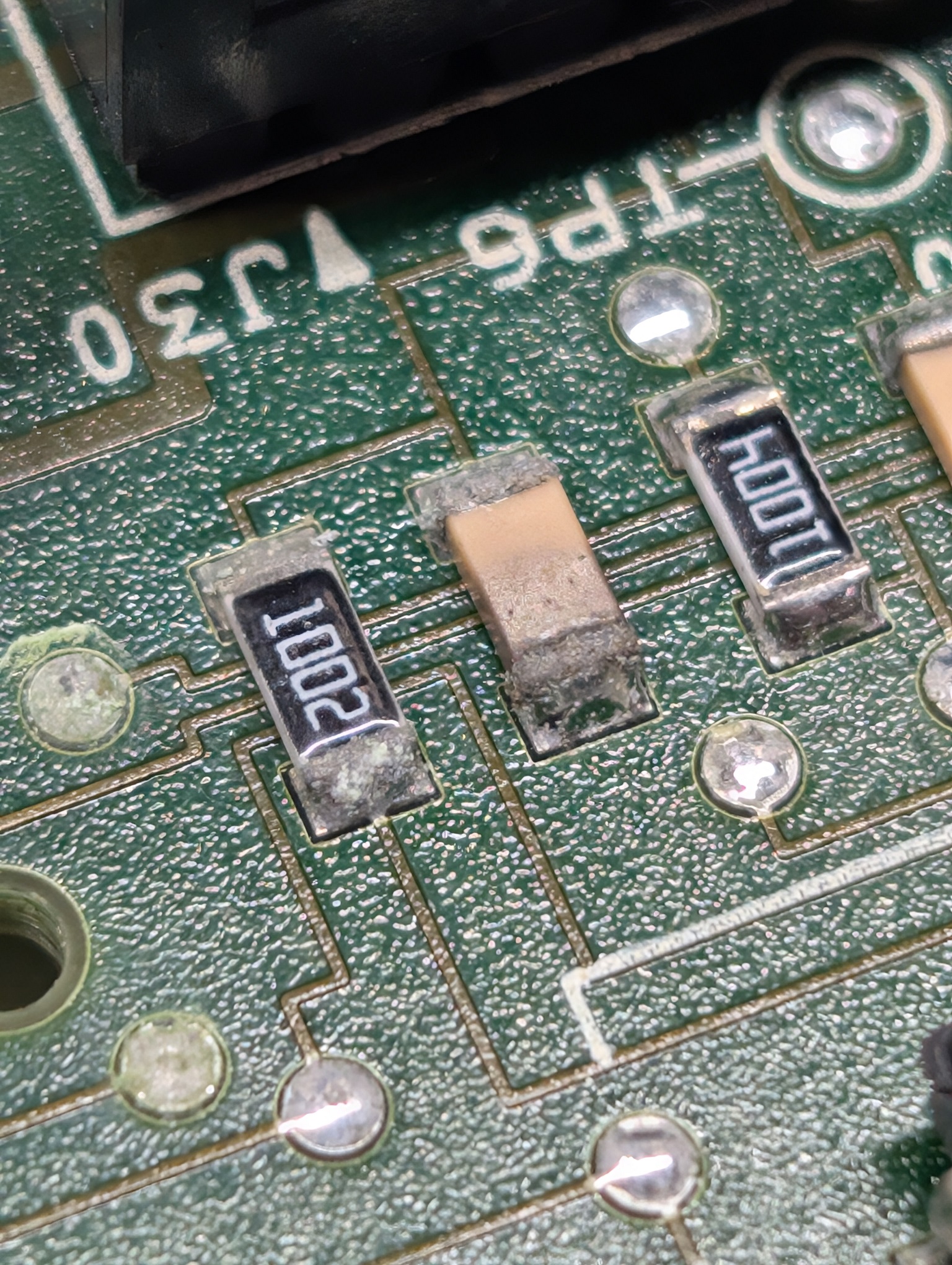

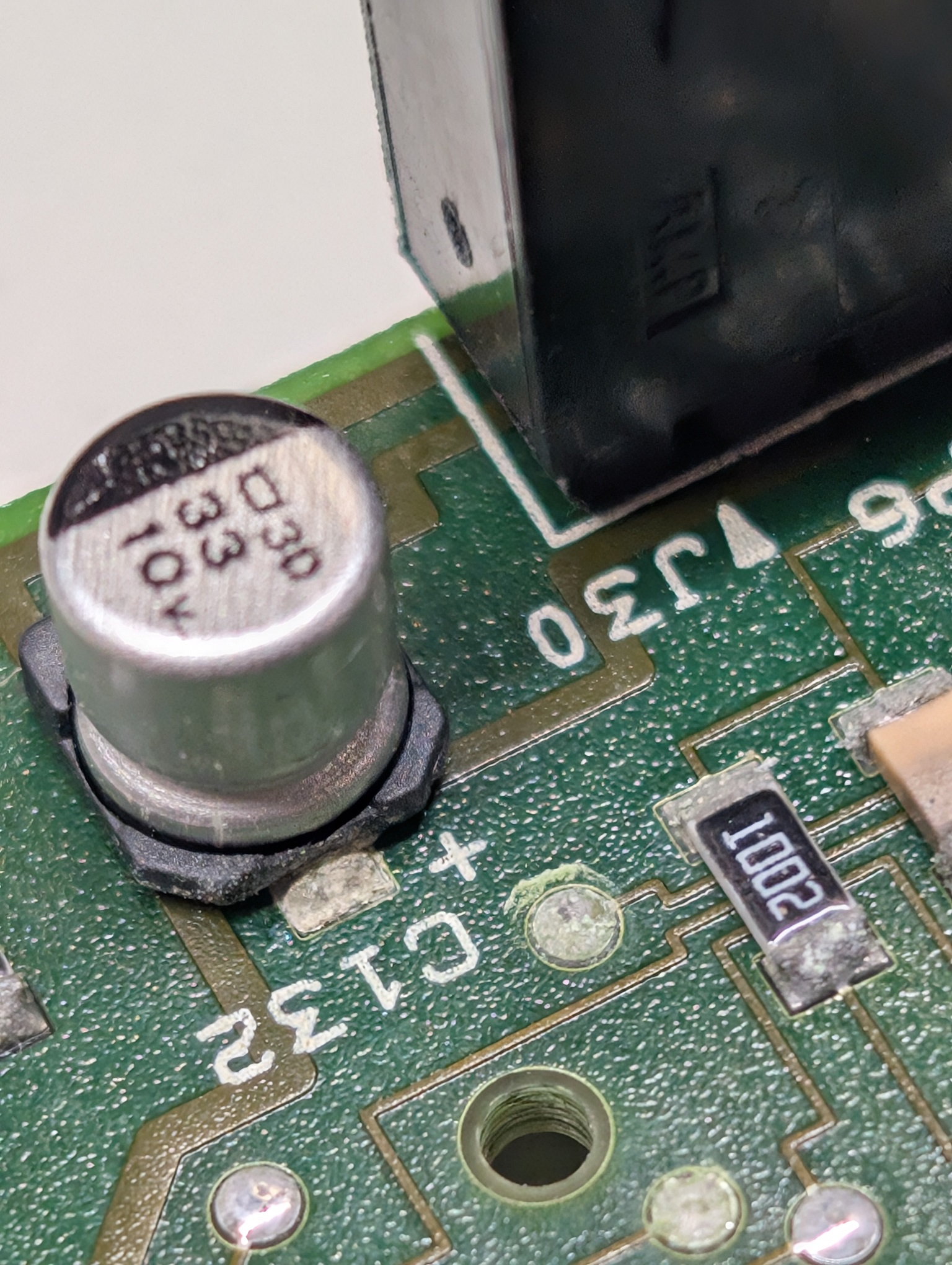

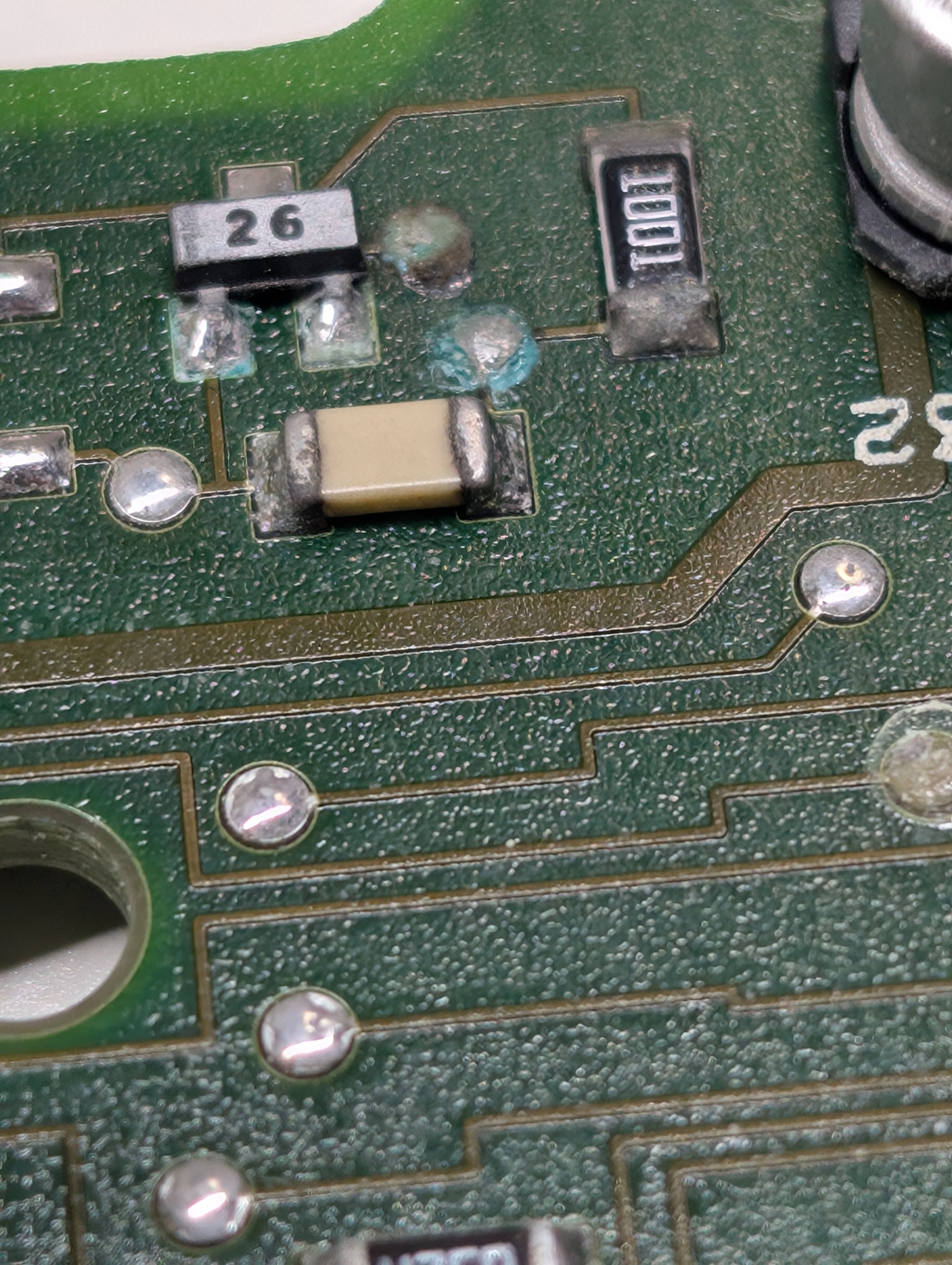

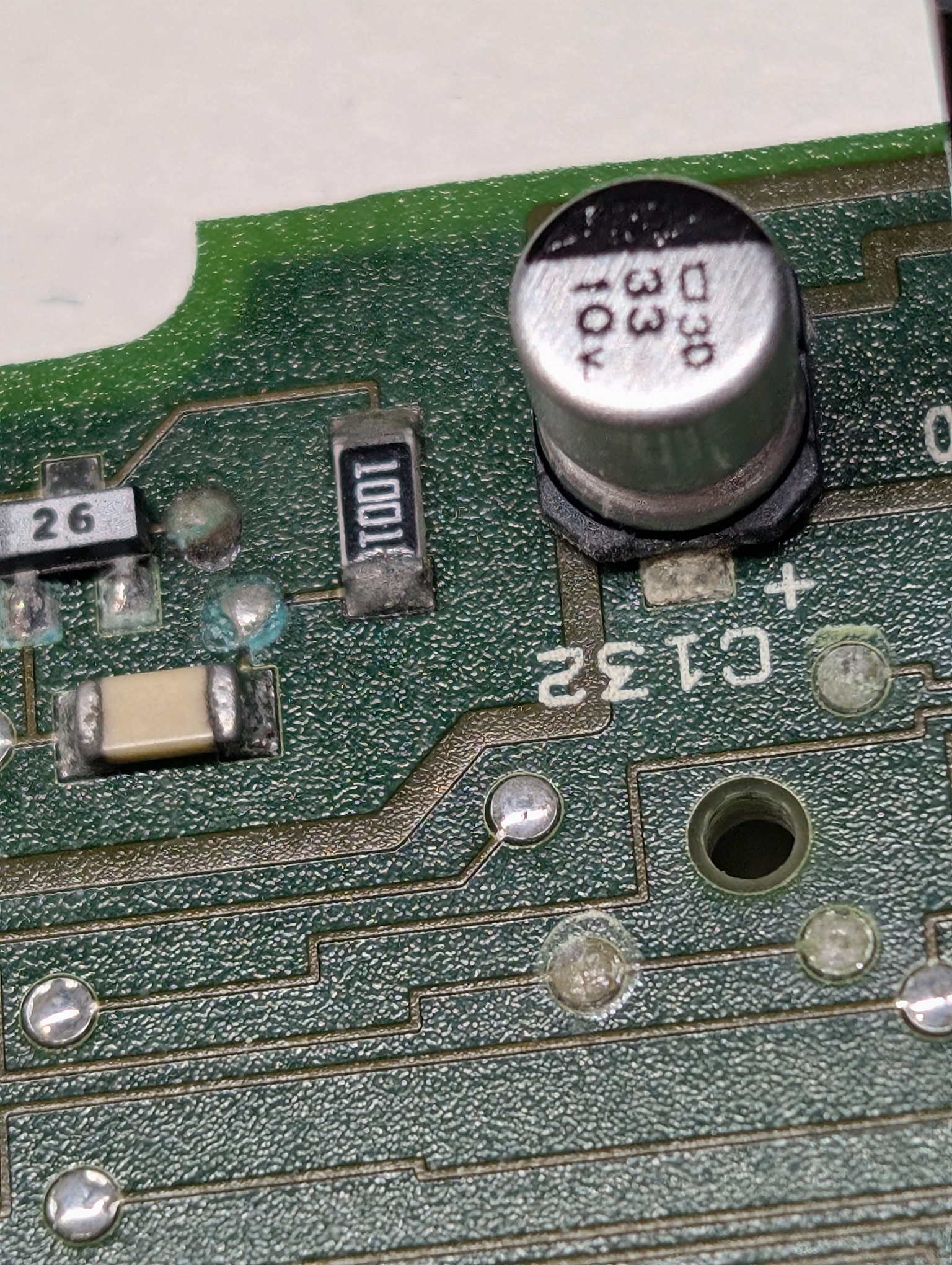

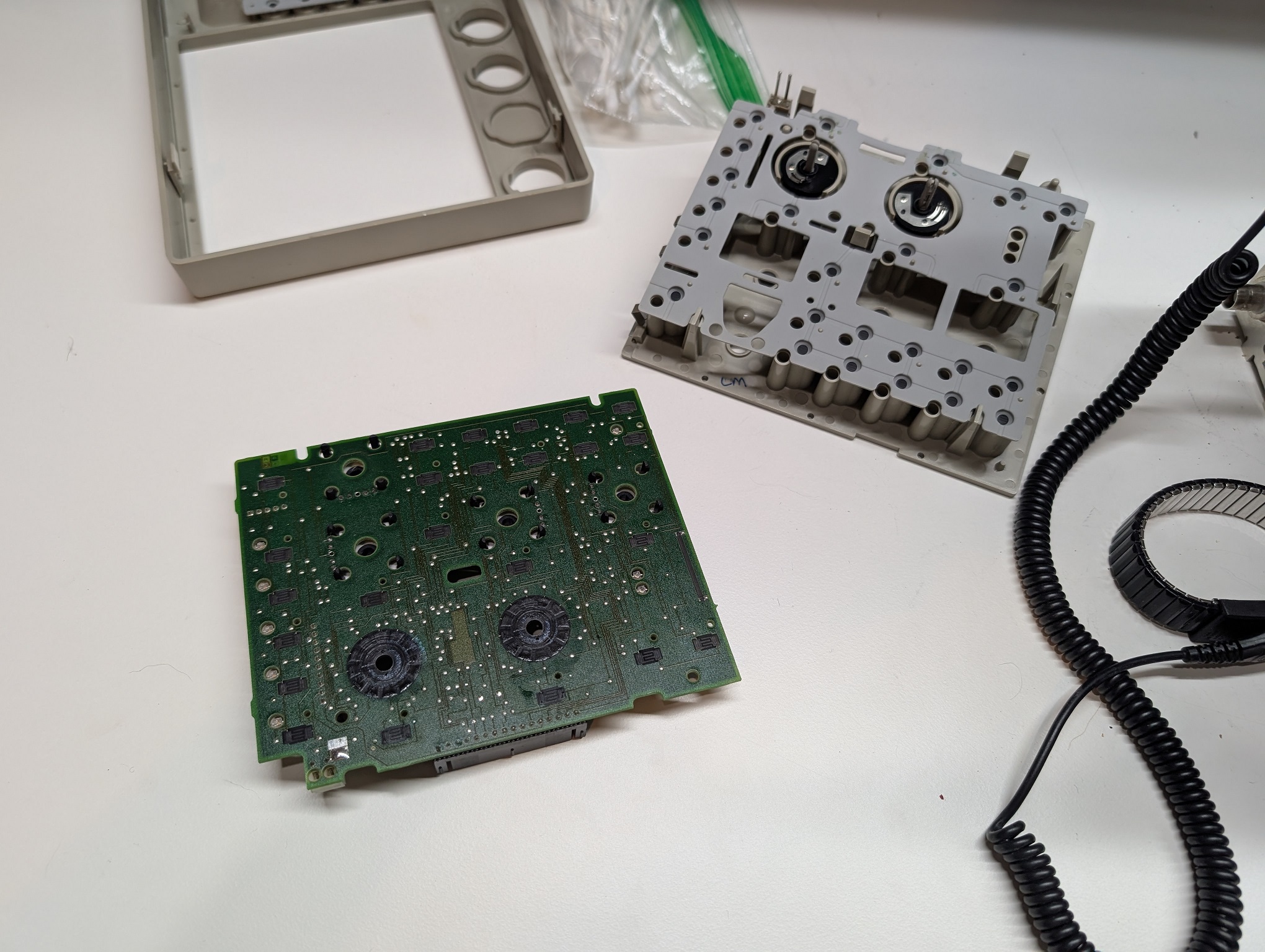

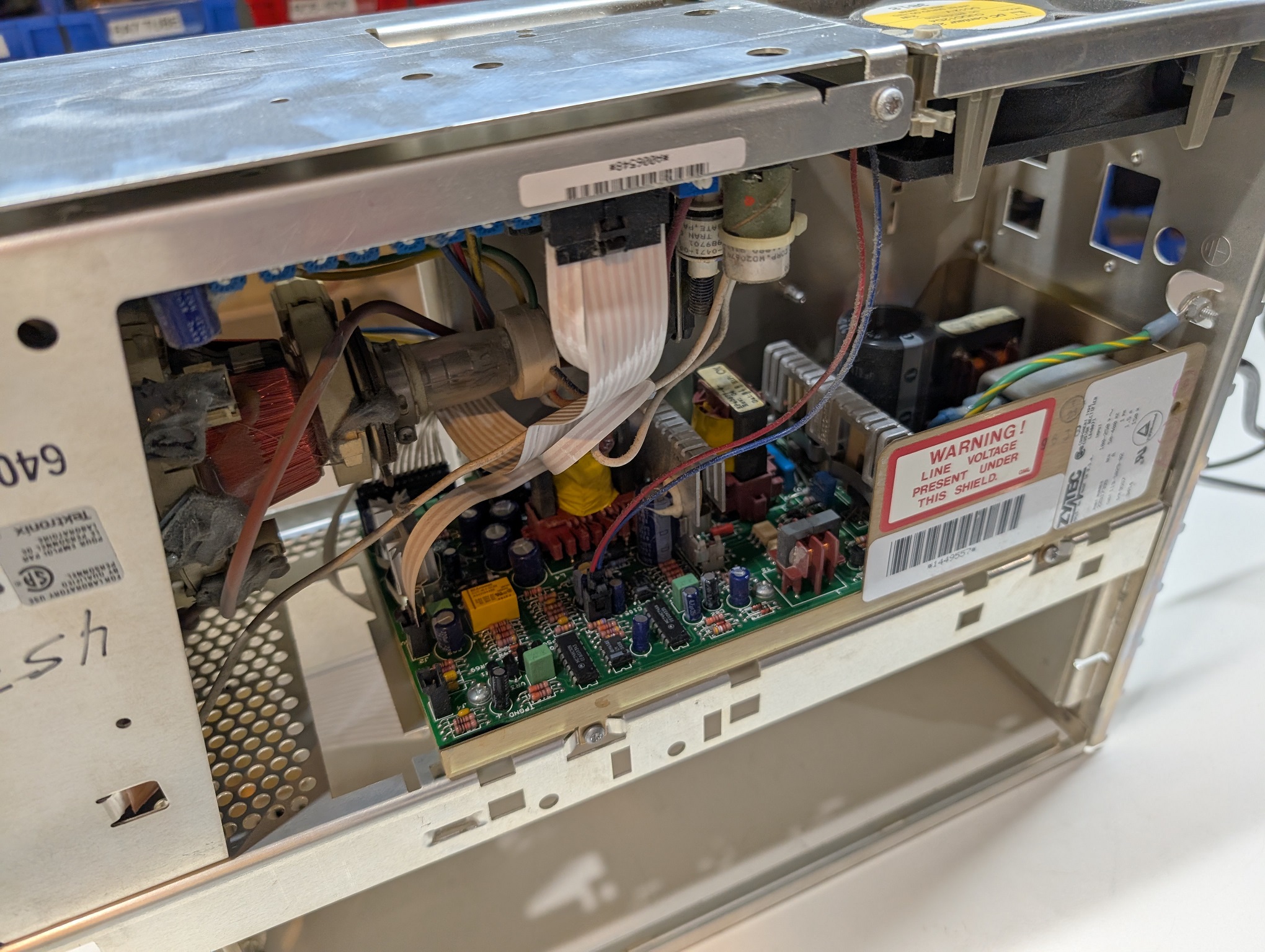

The troubleshooting diagram points to the main board (Main CPU plus the front end). But when I took a closer look at the Front Panel unit, I noticed this:

Also some oxidation in the connector that I have touched up.

Some of it are electrolytic caps, that I will need the solder tweezers to lift up, and I only have them at work, and I am back to work on 10th.

Overall, I am not impressed with the PCB routing by Tektronix, or whoever did it for them. Even if this is not the problem.

I guess, if these capacitors leaked, it is not their fault. But what I do not know, how those vias got oxidized. Vapors from leaking caps?

Worst case, I will buy a new board, but only if the price makes sense.

I though at the time, it was working.

When I turned it on, the traces were there but the Front Panel buttons and controls did not work.

After many power-ups it would work, then would cease to work....after warm-up it could work for a long time and I wouldn't be able to stop it from working to troubleshoot.

The troubleshooting diagram points to the main board (Main CPU plus the front end). But when I took a closer look at the Front Panel unit, I noticed this:

Also some oxidation in the connector that I have touched up.

Some of it are electrolytic caps, that I will need the solder tweezers to lift up, and I only have them at work, and I am back to work on 10th.

Overall, I am not impressed with the PCB routing by Tektronix, or whoever did it for them. Even if this is not the problem.

I guess, if these capacitors leaked, it is not their fault. But what I do not know, how those vias got oxidized. Vapors from leaking caps?

Worst case, I will buy a new board, but only if the price makes sense.

People who do not drink, do not smoke, do not eat red meat will one day feel really stupid lying there and dying from nothing.

![[-] [-]](https://philcoradio.com/phorum/images/bootbb/collapse.png)