04-10-2017, 11:40 AM

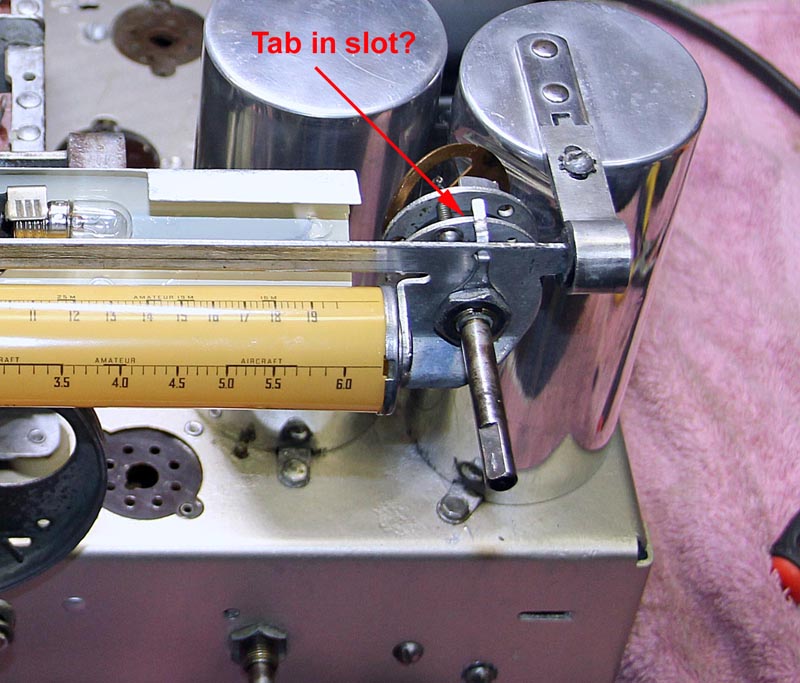

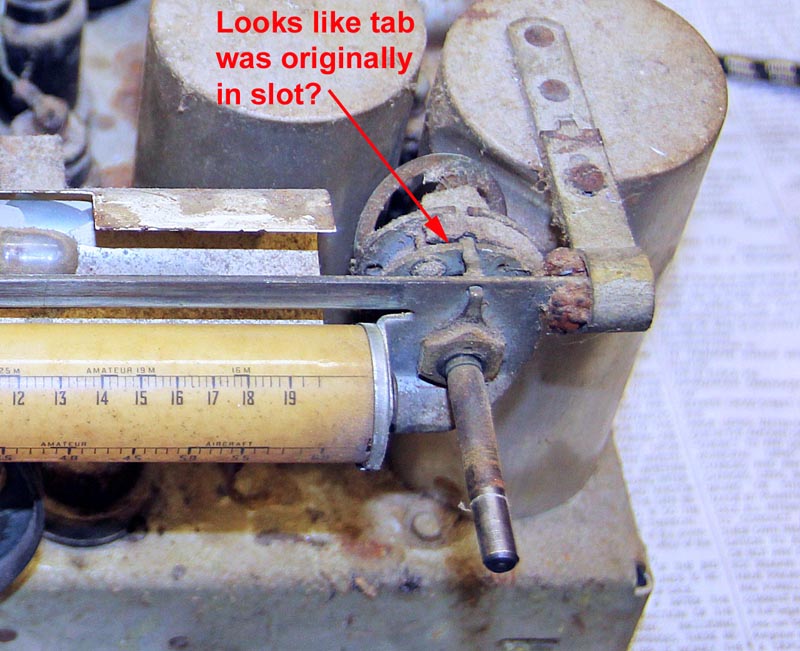

I am having trouble understanding the operation of the vernier control on my GE A-70. I took it apart and cleaned, lubricated it and re-installed it with along with re-stringing the rotating dial. Everything works great except the pointer does not move during fine adjustment. There is only one shaft which I think should automatically switch from fine to coarse when the pin hits the stop on the rear of the control (I attached photos showing the pin and tab).

If I place the tab on nut into the slot on the front of the vernier it prevents the control from switching to coarse and limits the dial travel. However it appears from my photo of the original set up that the tab is in the slot so I am confused. can anyone shed some light on how this control is supposed to be set up.

Thanks,

Steve D

If I place the tab on nut into the slot on the front of the vernier it prevents the control from switching to coarse and limits the dial travel. However it appears from my photo of the original set up that the tab is in the slot so I am confused. can anyone shed some light on how this control is supposed to be set up.

Thanks,

Steve D

![[-] [-]](https://philcoradio.com/phorum/images/bootbb/collapse.png)