RCA V-210 field coil removal

Posts: 116

Threads: 25

Joined: Jul 2006

City: Lebanon, NJ 08833

Thanks, EdHolland. I found an old 5lb spool of non ROHS 34AWG magnet wire here at work and we have an old winding machine that is used for prototyping which I can use. I just have to design a mandrel to mount and hold the bobbin.

I measured and calculated the voice coil gap to be about 0.040" and the diameter is 1", so to center the pole piece when pressing it back in I need to find a circular tube of that thickness and outer diameter. It can be metal, plastic, FR4 or even cardboard as long as it centers the pole piece and doesn't move as I press it it. We have a number of FR4 tubes that we use for bobbins and HV insulators here at work so I will have to search through them and hopefully I'll find a suitable one or one that I can machine to the proper dimensions.

Steve D

Posts: 2,118

Threads: 112

Joined: Jun 2010

City: Medford OR (OR what?)

One of the biggest issues with rewinding is supporting the coil-form cheeks. So wen you build your mandrel, try to add some large washers to keep the wire from making the coil "fat".

"I just might turn into smoke, but I feel fine"

http://www.russoldradios.com/

Posts: 116

Threads: 25

Joined: Jul 2006

City: Lebanon, NJ 08833

You are right, Phlogiston, I removed all the winding wire from my coil and the bobbin is intact but very fragile. The cheeks are thin cardboard and will deform when winding. My next task it to design a mandrill and cheek support.

I want the coil to appear original and if the sides are too flimsy I'll make new ones from a different material and cover them with the old cardboard ones. Some experimenting to do.

Steve D

Posts: 5,220

Threads: 275

Joined: Nov 2012

City: Wilsonville

State, Province, Country: OR

Nice work! More than I would take on but you might save this one!

Posts: 116

Threads: 25

Joined: Jul 2006

City: Lebanon, NJ 08833

So I finally got some time to work on the field coil this past weekend. I made a new bobbin from some 0.030" FR4 sheet and 1.25"OD, 0.062" wall thickness FR4 tube.

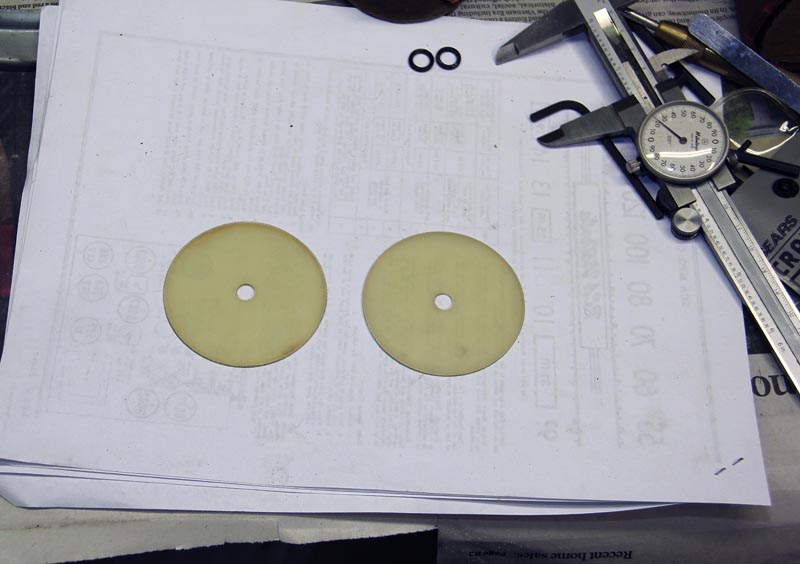

Cutting the bobbin cheeks with a fly cutter:

Pieces ready for assembly:

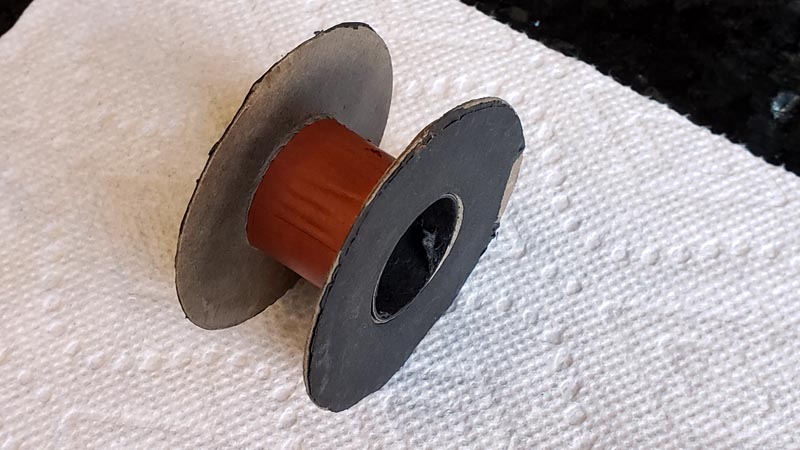

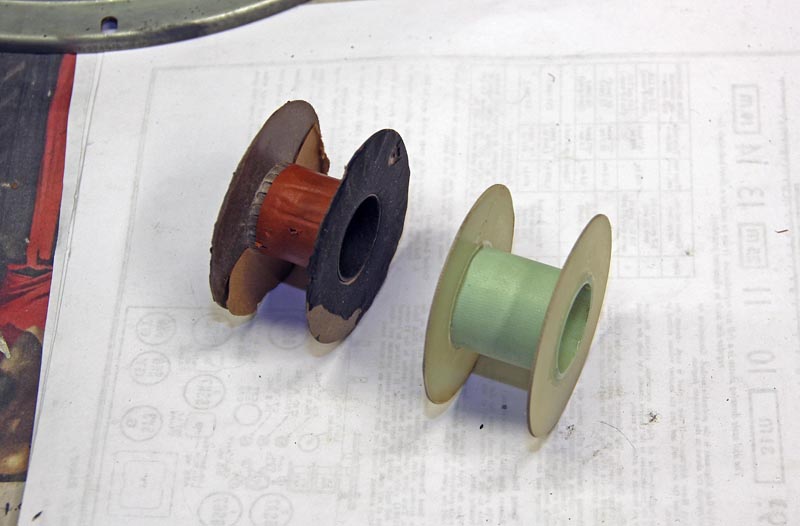

Next I epoxied the cheeks to the tube (original bobbin shown for reference):

Lastly I painted the bobbin flat black to match the original:

Posts: 116

Threads: 25

Joined: Jul 2006

City: Lebanon, NJ 08833

Another shot of the new bobbin:

The next step is to make a setup to allow unspooling of the wire while maintaining tension and a method to guide the wire across the bobbin.

Steve D

Posts: 116

Threads: 25

Joined: Jul 2006

City: Lebanon, NJ 08833

Continued from the previous post:

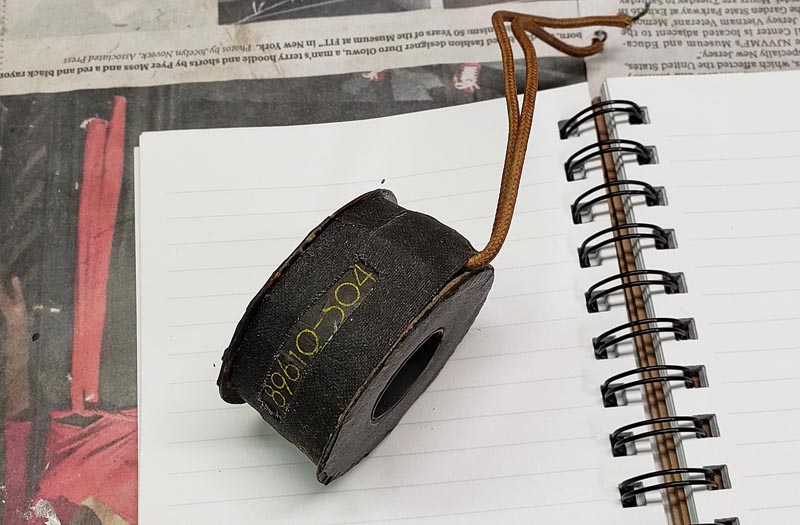

Finished coil:

The coil fits the pole piece and speaker frame perfectly, so the next step is to press the pole piece back into the frame while maintaining a uniform .032” voice coil gap.

After I wound this coil, out of curiosity, I re-glued the FR4 bobbin with JB weld and using the side supports wound another coil. It also wound perfectly, so now I have a spare coil or a nice inductor for any filtering needs.

Steve D

The coil fits the pole piece and speaker frame perfectly, so the next step is to press the pole piece back into the frame while maintaining a uniform .032” voice coil gap.

After I wound this coil, out of curiosity, I re-glued the FR4 bobbin with JB weld and using the side supports wound another coil. It also wound perfectly, so now I have a spare coil or a nice inductor for any filtering needs.

Steve D

Posts: 116

Threads: 25

Joined: Jul 2006

City: Lebanon, NJ 08833

Finishing up the speaker:

I made the centering collar from four strips of 0.010 Teflon material which is what I had on hand and cut each piece successively longer to maintain the same length when wrapped around the pole piece. This resulted in a thickness of nominally 0.040 and the gap appears to actually be closer to 0.038” and when compressed into the slot, fit nice and evenly tight all around.

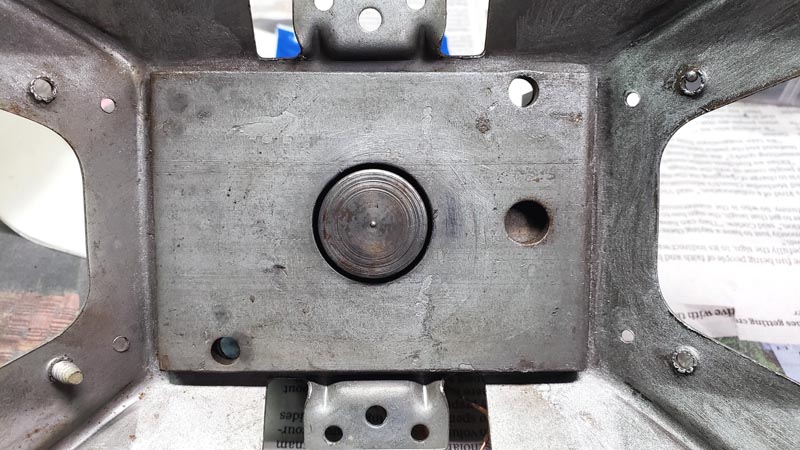

With this arrangement I was able to easily press the pole piece back in and the resultant gap was beautifully uniform:

With this arrangement I was able to easily press the pole piece back in and the resultant gap was beautifully uniform:

Next I used small strips of .007” paper to center the voice coil while I screwed the spider assembly in and glued the edges of the cone. I had to remove the cone center cap to access the voice coil to insert the centering strips:

Next I used small strips of .007” paper to center the voice coil while I screwed the spider assembly in and glued the edges of the cone. I had to remove the cone center cap to access the voice coil to insert the centering strips:

Continued in next post.

Steve D

Posts: 116

Threads: 25

Joined: Jul 2006

City: Lebanon, NJ 08833

Lastly, I glued the cone center cap back on and made all the electrical connections:

Now I just have to finish refurbishing the chassis to power it up. Hopefully it will play clearly.

This was a lot of work and a good experience and I’m glad I saw it through, but next time perhaps I’ll try harder to find a replacement speaker.

Steve D

Now I just have to finish refurbishing the chassis to power it up. Hopefully it will play clearly.

This was a lot of work and a good experience and I’m glad I saw it through, but next time perhaps I’ll try harder to find a replacement speaker.

Steve D

Posts: 16,582

Threads: 574

Joined: Oct 2011

City: Jackson

State, Province, Country: NJ

Great job!

Laborious process too.

People who do not drink, do not smoke, do not eat red meat will one day feel really stupid lying there and dying from nothing.

Posts: 112

Threads: 36

Joined: May 2015

City: Brandon, SD

I had a replacement speaker the whole time, just never heard from you again....

Posts: 116

Threads: 25

Joined: Jul 2006

City: Lebanon, NJ 08833

Success, I got the chassis working and the speaker sounds great; loud and clear with no rattling, rubbing or distortion. The field coil drops the correct voltage and I Just need to do an alignment and refurb the turntable and cabinet. This was an enjoyable but laborious process which was worthwhile as I gained experience in speaker design but I probably would only do it again for a speaker that is unobtainum.

Steve D

Users browsing this thread:

|

|

Recent Posts

|

|

Part numbers to model cross

|

| That I wouldn't know, but sometimes the radio document itself shows one, same as the capacitor cans' etc pinouts.morzh — 12:46 PM |

|

Part numbers to model cross

|

| Thank you morzh, that is exactly what I was looking for. Now , is there some where that shows pinouts for Philco power ...Jim Dutridge — 11:37 AM |

|

Restoration of the Canadian General Electric A-87

|

| Thanks for your help Michael. In fact, this video is only an intermediate result. Later I had to apply another tinting l...RadioSvit — 09:01 AM |

|

Restoration of the Canadian General Electric A-87

|

| Great job on the cabinet.

PS. In the US notation, "kenotron" refers to specific type of tubes; we call re...morzh — 08:24 AM |

|

Part numbers to model cross

|

|

This document has at least some tables of models and parts used.

Example: Choke 32-7572, used in 604 radio.

Search f...morzh — 08:19 AM |

|

Restoration of the Canadian General Electric A-87

|

| I also checked all the radio tubes on my Hickok 530 tube tester. The 5Z3 kenotron turned out to be faulty, all the other...RadioSvit — 08:02 AM |

|

Restoration of the Canadian General Electric A-87

|

|

Well... While the varnish is drying up, I started repairing the chassis...

Of course I started by replacing the pa...RadioSvit — 07:12 AM |

|

Philco Model 38-7: what caps & resistors do fail typically?

|

| Hello Martin,

Welcome aboard our little community what great Model 38-7

Sincerely Richardradiorich — 12:30 AM |

|

Philco Model 38-7: what caps & resistors do fail typically?

|

| Welcome to the Phorum Martin.

I count about 9 paper caps, the 3 electrolytic caps and 2-Y2 safety caps to replace th...RodB — 09:44 PM |

|

Part numbers to model cross

|

| Jim,

We have this index put together by Dale Cook but I don't think that is quite what you are looking for.

The Parts...klondike98 — 09:37 PM |

|

Who's Online

|

| There are currently no members online. |

|

|

![[-] [-]](https://philcoradio.com/phorum/images/bootbb/collapse.png)