The fix was easier than I first thought. Given the construction of the push button switch assembly, it would have required some major disassembly to install a switch that was held in place by a nut. Also, I didn’t just want to epoxy a new switch in place as that can be a mess to deal with if the switch would ever need to be replaced in the future.

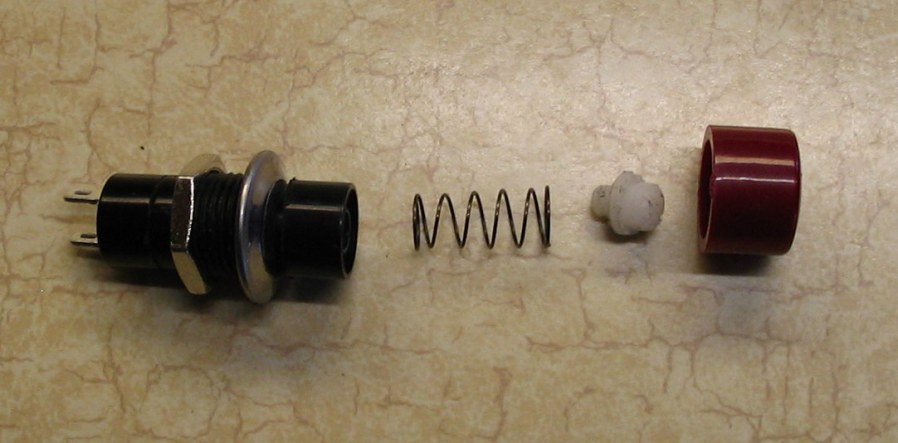

I used the Radio Shack 275-0011 switch recommended by Ron. I started by pulling the red pushbutton off and unscrewing the small white spring retainer and spring from the plunger. The black switch body had sort of a collar around the plunger, I guess to provide some protection for the plunger. Anyway, I cut this off with a razor saw as shown in the second picture. This made it possible for the plunger to fit into the hole in the back of the push button assembly. The length of the plunger was just the right length for the metal actuator to operate the switch properly.

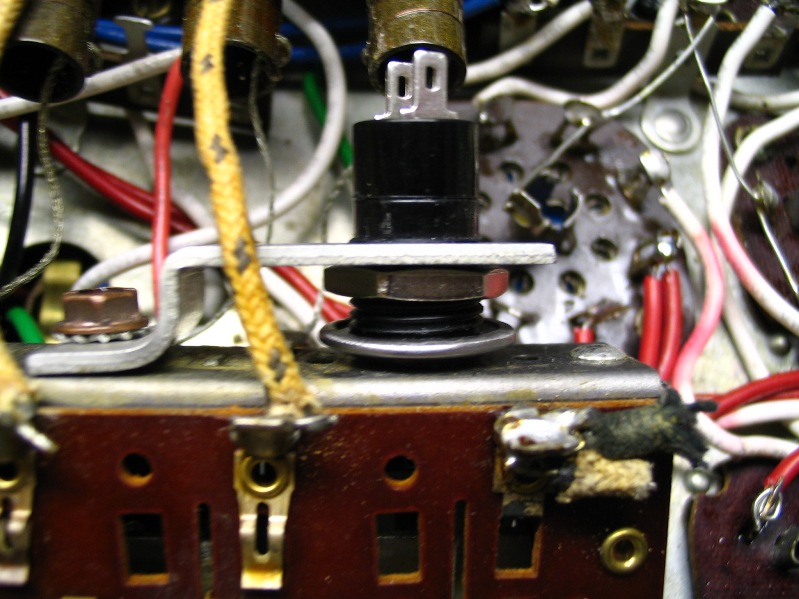

As I mentioned, I didn’t want to simply epoxy the switch in place, so I positioned the switch retaining nut at the end of the threaded portion of the switch and used that as a stop that the original bracket could contact to keep the switch in place. This is shown in the third photo.

The whole thing took less time to do than it’s taken to describe it. Hope my description makes sense.

I haven’t powered it up yet as I have a bunch of work left to do. I will put just a bit of epoxy on the nut and the bracket to make sure they don’t come loose.

As an aside, the original bracket and switch (shown in a previous post) certainly looks like a “factory” job. The bracket wasn’t handmade, it was obviously stamped out on a machine. Also, there was no adjustment for how far the plunger protruded into the push button assembly – the depth was determined by the dimensions of the bracket. The only adjustment was from side to side. The hole for the switch was elongated to allow lateral adjustment to insure that the plunger was centered in the hole. Given how hard it would have been to replace a stock switch that might go bad, I wonder if Philco came up with this as a quicker, lower cost alternative?

Thanks for everyone’s input!!

![[-] [-]](https://philcoradio.com/phorum/images/bootbb/collapse.png)