Posts: 891

Threads: 51

Joined: Feb 2013

City: Shenandoah,

State, Province, Country: Pennsylvania

Howard, did you reinsert that pin that I mentioned using a magnet to extract? I believe it is what finally holds the whole assembly together!

Ron

Bendix 0626. RCA T64 Philco 20B

Philco 41-250. Philco49-500

GE 201. Philco 39-25

Motorola 61X13. Philco 46-42 Crosley 52TQ

Philco 37-116. Philco 70

AK 35 Philco 46-350

Philco 620B. Zenith Transoceanic B-600

Philco 60B. Majestic 50

Philco 52-944. AK 84

Posts: 16,577

Threads: 574

Joined: Oct 2011

City: Jackson

State, Province, Country: NJ

Ron

I am not sure he could make the assembly stay together in the first place.

People who do not drink, do not smoke, do not eat red meat will one day feel really stupid lying there and dying from nothing.

Posts: 41

Threads: 2

Joined: Mar 2025

City: Puyallup

State, Province, Country: WA

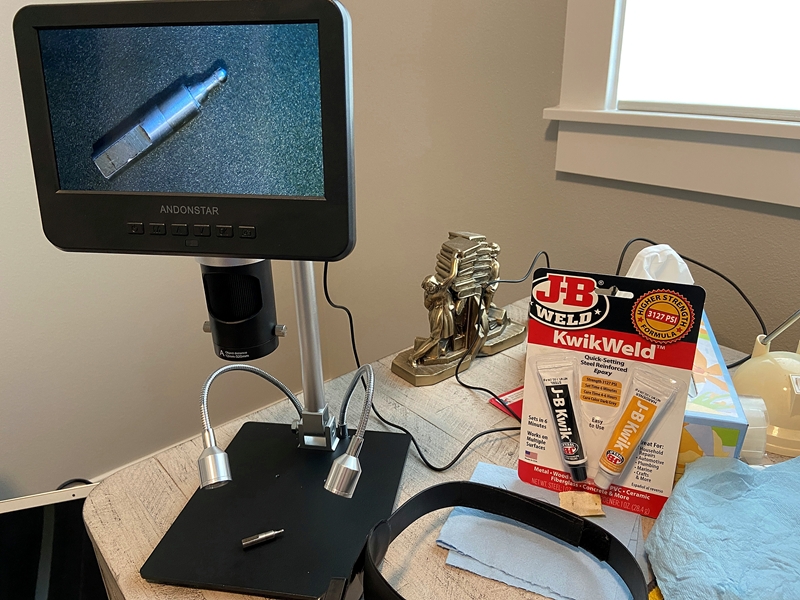

Wow morzh, you have access to some very useful doc. That cross-section (Fig 2) is dynamite.

As you can see, if the ball wasn't attached to the vernier shaft, the shaft would simply back/fall out. Which is exactly what happens to mine now.

Starting tomorrow I'm gonna start calling some of these local Boeing fab shops that do the small custom fabrications. Even if they won't reattach it for me, they might tell me what the best method for doing so is.

Thanks.

Btw, here's a pic of a different '30s Philco radio fine tuning mech. It's a different model but they used the same method for implementing vernier control. Note the ball-end.

All-American Five Philco 54C – Part 5 – Philco Library

(This post was last modified: 03-16-2025, 03:58 PM by HowardWoodard.)

Posts: 41

Threads: 2

Joined: Mar 2025

City: Puyallup

State, Province, Country: WA

Hi Ron. Yes, I got it all back together the first time, after getting it all cleaned and lubed, and it was working really nice. It was while I was inserting the pin you refer to that holds the coarse shaft -- thus the entire assembly -- in place that the end-ball came off the vernier shaft.

Posts: 16,577

Threads: 574

Joined: Oct 2011

City: Jackson

State, Province, Country: NJ

I think that's the one I have in Philco 60, which I have recently fixed.

The last robodial radio repair (38-690) happened in 2017, and I simply forgot how I did that. I remember the pin did not want to come out.

But for the life of me I do not recall the ball at the end and what I did about it.

The end of the shaft then should be concave so the ball readily goes into it when glued.

People who do not drink, do not smoke, do not eat red meat will one day feel really stupid lying there and dying from nothing.

Posts: 41

Threads: 2

Joined: Mar 2025

City: Puyallup

State, Province, Country: WA

It is concave and the balls rests in it about 25%-33% of the circumference of the ball. I'm just contemplating which would be the strongest option -- epoxy, super glue or silver solder -- before I put it back together.

Posts: 16,577

Threads: 574

Joined: Oct 2011

City: Jackson

State, Province, Country: NJ

Looking at the drawing, the ball should be glued well, as it seems that it rolling against the 3 other balls is what provides the planetary action. And the ball is probably a polished/plated metal, so not every adhesive will stick to it well.

Probably need to find out an adhesive specifically for it.

I wonder if it was too complex for them to machine the shaft such that it would have the ball-shaped end. Probably would be.

People who do not drink, do not smoke, do not eat red meat will one day feel really stupid lying there and dying from nothing.

Posts: 41

Threads: 2

Joined: Mar 2025

City: Puyallup

State, Province, Country: WA

I think you’re right about everything. A couple years later they were machining it out of a single piece of metal. Still had the issue of needing the end- ball to be hardened.

At any rate, needing to get the ball attachment right and knowing nothing about adhesives or metallurgy, I’m being deliberate.

As much as I enjoy re-lifeing things, if I run across a complete tuning shaft assembly or even just a complete vernier shaft, I’m gonna buy it.

(This post was last modified: 03-17-2025, 12:04 PM by HowardWoodard.)

Posts: 1,199

Threads: 49

Joined: Oct 2017

City: Allendale, MI

Are you sure that the flange at the end of the shaft isn't just completely worn off or bent over causing the indentation that looks like it should hold the ball bearing.? If I remember correctly on my 37-116's and my 38-116, the flange that pushed against the 3 ball bearings was machined in and the purpose of the ball was a bearing point for the spring to push against to reduce wear and friction. the picture you have of the AA5 shaft is the correct shape. The 3 balls may have frozen in the shaft and when the fine shaft was turned, it caused a lot of wear, eventually wearing the flange completely away.

Here is a photo of one from a Scott 16 where the fine shaft was worn out. I had to make a new one on a lathe. It works the same way. The spring pushed on a ball bearing which then pushed on the end of the fine shaft. The 3 ball bearings ride in the groove and are pushed against the flange. The outer housing (not shown) holds the ball bearings in place. As Morzh said, a planetary arrangement.

(This post was last modified: 03-16-2025, 11:05 PM by rfeenstra.)

Posts: 41

Threads: 2

Joined: Mar 2025

City: Puyallup

State, Province, Country: WA

As you might have already surmised, I’m not sure of anything. You raise a good question, and your pic gives it credibility. Did you make that shaft on your lathe? Pretty impressive.

In this case my guess is based on seeing another one from the same magnetic tuner that fits my guess.

(This post was last modified: 03-17-2025, 12:12 PM by HowardWoodard.)

Posts: 41

Threads: 2

Joined: Mar 2025

City: Puyallup

State, Province, Country: WA

Well, my epoxy didn't hold.

It looks like I'm stuck until I can locate another vernier shaft or tuning assembly. ... or find someone who can fabricate a replacement for me.

Posts: 1,199

Threads: 49

Joined: Oct 2017

City: Allendale, MI

I have a chassis for another 38-116. If I get a chance tonight (don't count on it!) I'll disassemble and see what's inside. If I can get to it, I'll take some pics.

Rob

Posts: 41

Threads: 2

Joined: Mar 2025

City: Puyallup

State, Province, Country: WA

That would be beyond great Rob. Fingers crossed...

Howard

Posts: 1,199

Threads: 49

Joined: Oct 2017

City: Allendale, MI

Posts: 41

Threads: 2

Joined: Mar 2025

City: Puyallup

State, Province, Country: WA

I can't believe you did that, but I sure am appreciative. It validates my conjecture about how it would have worked before the end-ball separated. I don't see any residue around where the ball mates with the shaft which is what I would expect to see for soldering, brazing, or any other wicking process, so the joining remains a mystery.

A simpler and more durable design would have been to have the vernier shaft end in a reverse cone tall enough to act as the restraint against the three ball bearings. If I had a lathe and knew what I was doing, I would give that a try. ...and if frogs had wings, they wouldn't need shock absorbers...

So a 38-116 could be a donor. I wonder what other models could be donors? It would help to know.

Thanks again and I'll continue trying to find another working drive unit to purchase.

Howard

Puyallup, WA

Users browsing this thread: 1 Guest(s)

|

|

Recent Posts

|

|

Philco 42-345 Restoration/Repair

|

| Hang in there...PaulPaul Philco322 — 09:30 PM |

|

Philco 42-345 Restoration/Repair

|

| The thrill is gone again, thought I was close to being done with it. Well Friday it was receiving broadcast, Saturday mo...osanders0311 — 07:47 PM |

|

Help with Supreme 599

|

| Iam getting closer to fixing it. I bumped

Up the tranny voltage to get 5v on the 80 tube. I gan get the needle to move ...daveone23 — 03:41 PM |

|

Philco 42-345 Restoration/Repair

|

| Hello RodB,

Checking my previous post I realized you're the one with the 42-340. I replaced the string for the tuning...osanders0311 — 03:12 PM |

|

5U4 vs 5Z4 tubes

|

| I saw no evidence of anything going wrong.

The transformer is fused already which is nice.

Interestingly the 5z4 did...bridkarl — 02:37 PM |

|

5U4 vs 5Z4 tubes

|

| I doubt anything cooked in 30 seconds because of the oops! These are very similar tubes, and nothing but transformer re...GarySP — 02:30 PM |

|

Restoration of the Canadian General Electric A-87

|

|

Paul Philco322.You will be keeping very busy, you may have to go back to work for a breakIcon_smile. Paul

To rel...RadioSvit — 01:57 PM |

|

5U4 vs 5Z4 tubes

|

| I grabbed the wrong tube and put in a 5U4 tube instead of the 5Z4 - I just had the rectifier in with no other tubes.

Af...bridkarl — 01:54 PM |

|

Restoration of the Canadian General Electric A-87

|

| After applying the filler to the entire body, I noticed that the shades of the facade and the side and top walls were ve...RadioSvit — 01:49 PM |

|

Restoration of the Canadian General Electric A-87

|

| You will be keeping very busy, you may have to go back to work for a break:). PaulPaul Philco322 — 01:46 PM |

|

Who's Online

|

There are currently 536 online users. [Complete List]

» 2 Member(s) | 534 Guest(s)

|

|

|

|

|

![[-] [-]](https://philcoradio.com/phorum/images/bootbb/collapse.png)