Posts: 13

Threads: 6

Joined: Nov 2022

City: FEDERAL WAY

State, Province, Country: WA

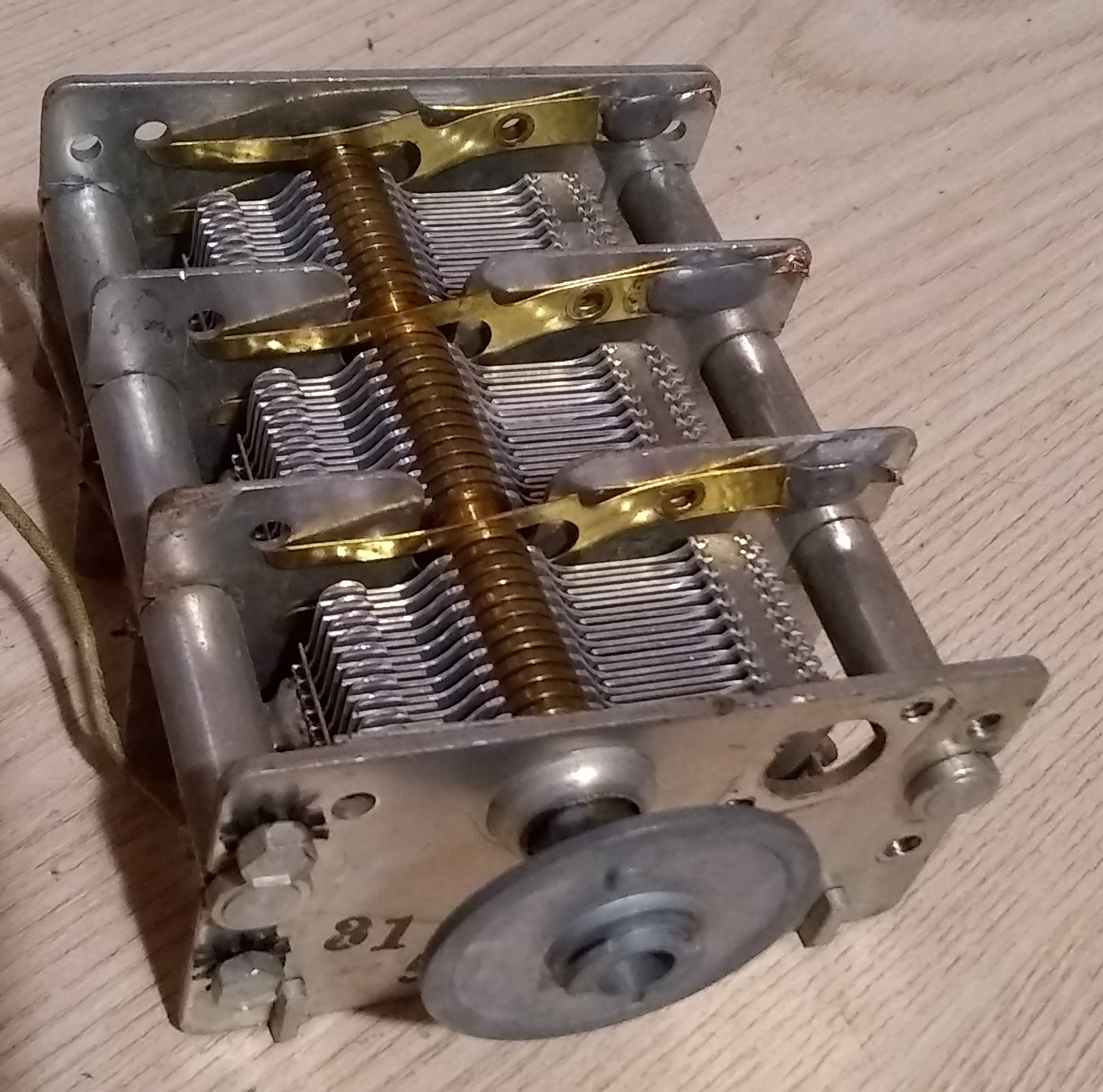

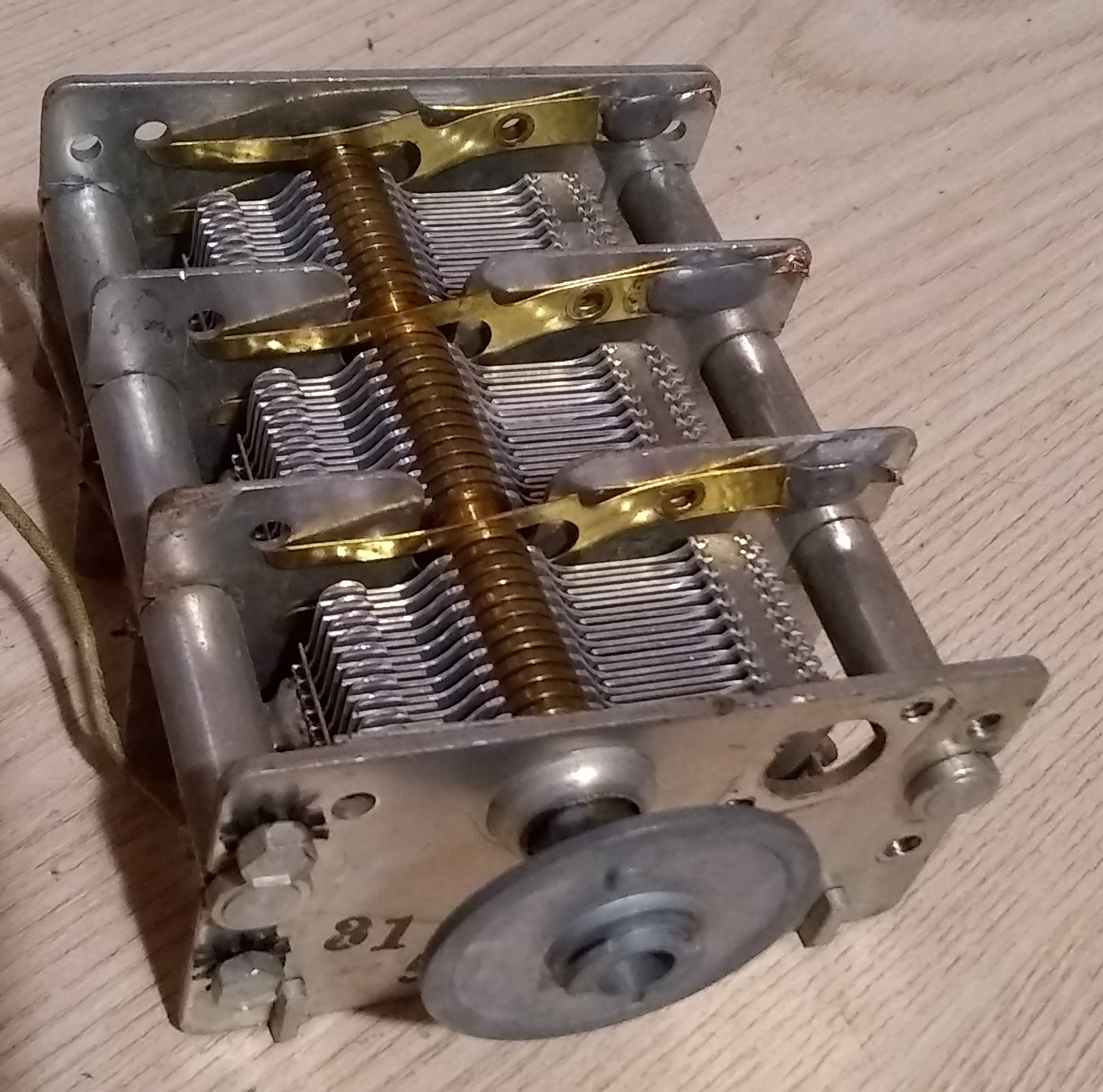

The tuner from my 620B turned out great after being ultrasonically cleaned.

I forgot to remove and disassemble the little "gearbox" assy. for the coarse and fine tuning. And when I removed it i saw that the cleaner didn't reach inside, and there was a very tarry goo in there.

After cleaning it I used white grease and reassembled it, but it doesn't turn smoothly and the fine tuning gear stops and starts. I may have reassembled it wrong. Its a strange mechanism and I don't understand the purpose for the spring and smaller ball. Anyone have experience with this?

Posts: 1,288

Threads: 11

Joined: Jul 2020

City: Greenlawn

State, Province, Country: NY

The shafts are concentric. The gear is on the coarse shaft. This should smoothly operate the tuning cap without the fine shaft in place.

Is the fine shaft tapered? The small ball likely goes in first, followed by the spring and shaft. With the fine (inner) shaft pressed as far as possible into the coarse (outer) shaft, add the 3 large balls and grease (Dunno if the balls should be greased, what did that area look like when you took it apart), insert into the collar, install the clip and release the shaft. The 3 large balls should rest in the groove on the inside of the "collar". Turning the inner shaft should cause smooth movement of the outer shaft.

This is all theory on my part, as I never took one of these apart. Good luck.

PS, that cleaning job looks fantastic!

"Do Justly, love Mercy and walk humbly with your God"- Micah 6:8

"Let us begin to do good"- St. Francis

Best Regards,

MrFixr55

Posts: 13

Threads: 6

Joined: Nov 2022

City: FEDERAL WAY

State, Province, Country: WA

Well I took it apart again but didn't see anything obvious, but under magnification i noticed the shaft that the balls roll against was rough and the brass parts the balls fit in were sharp edged and uneven. Using a file and drill motor i filed the surfaces smooth and reassembled it with just oil and it works great now. Now I know it works i'll put some grease back in.

It had a groove on the inside race like MrFixr55 mentioned, but my theory is it was made from the balls and no lube rather than by design.

Posts: 1,288

Threads: 11

Joined: Jul 2020

City: Greenlawn

State, Province, Country: NY

Hi Promocom,

Glad you got it to work!!

BTW, what did you use as a cleaning agent in the ultrasonic cleaner?

"Do Justly, love Mercy and walk humbly with your God"- Micah 6:8

"Let us begin to do good"- St. Francis

Best Regards,

MrFixr55

Posts: 13

Threads: 6

Joined: Nov 2022

City: FEDERAL WAY

State, Province, Country: WA

Thanks MrFixr55... after regreasing it fine tuning didn't work reliably so ill reclean it and just use oil again.

i just use tap water and Purple Power from walmart, about half cup to 1/2 gallon water in my Harbor Freight unit.

Posts: 337

Threads: 13

Joined: Apr 2019

City: Greenwood

State, Province, Country: Delaware

Does it do anything to rust, promocom?

-simon

Posts: 13

Threads: 6

Joined: Nov 2022

City: FEDERAL WAY

State, Province, Country: WA

It doesn't do much to rust Simon, except knock off the loose bits. Maybe a media vibrating or tumbling unit would work better for that.

![[-] [-]](https://philcoradio.com/phorum/images/bootbb/collapse.png)