Tropic 53-960 restoration

Posts: 15,312

Threads: 530

Joined: Oct 2011

City: Jackson, NJ

15-minute soak in lacquer thinner didn't hlp either.

Will soak overnight.

People who do not drink, do not smoke, do not eat red meat will one day feel really stupid lying there and dying from nothing.

Posts: 13,776

Threads: 580

Joined: Sep 2005

City: Ferdinand

State, Province, Country: Indiana

Tar is going to laugh at a mere 200 degrees. As I said previously, sometimes the tar is on top, sometimes on the side. And sometimes both.

Good luck.

--

Ron Ramirez

Ferdinand IN

Posts: 15,312

Threads: 530

Joined: Oct 2011

City: Jackson, NJ

I followed the recommended 200F Arran suggested

People who do not drink, do not smoke, do not eat red meat will one day feel really stupid lying there and dying from nothing.

Posts: 4,614

Threads: 51

Joined: Sep 2008

City: Sandwick, BC, CA

Mike;

In truth I can't remember whether it was 200 or 250, but you don't want it too high or the cardboard will burn. I personally like the idea of putting the top back on the metal can even if the cardboard sleeve goes over top, it adds some extra structural integrity to the cardboard, and it's easy enough to join the two sections back together with aluminum duct tape if the cut is clean.

With regard to that phono jack I don't know what they were up to there, the usual method is to feed the signal into the grid of the 1st audio tube, or the top of the volume control. I don't know what they were up to in connecting the center of that jack to the plate of one of the power output tubes, and I've never seen a choke involved with a phono jack instal before, maybe they had some other intended purpose, five will get you ten it was a Ham operator that did it.

On those molded paper caps I think that Dennis Carter did drill the actual capacitors out of the plastic shells with a twist bit in a battery powered drill, they looked like those Sangamo "Little Chief" caps to me with the bright coloured shells. I don't know if the Bumble Bees are molded any differently, but one thing I do know is that they were no better then the run of the mill Aerovox waxies, unlike the Solar "Sealdtite" brand ones which are one of the few that are usually still functional.

Regards

Arran

Posts: 15,312

Threads: 530

Joined: Oct 2011

City: Jackson, NJ

Well,

I soaked it 24 hrs. Tonight I pulled the pickle out of the brine, grabbed one of the twist tabs with pliers, and the shell with my hand, pulled and the cap came out with the juicy "chwuak!"sound.

Black tar.

Removed most of it but decided to soak more to remove the rest.

I like this method more as gripping hot capacitor while trying to work fast as it is cooling fast is even less enjoyable.

People who do not drink, do not smoke, do not eat red meat will one day feel really stupid lying there and dying from nothing.

Posts: 13,776

Threads: 580

Joined: Sep 2005

City: Ferdinand

State, Province, Country: Indiana

...that's what heavy gloves and pliers are for.

P.S. Congratulations. I would not have thought soaking would be successful, given that the shell is foil over a very thick paper material.

--

Ron Ramirez

Ferdinand IN

Posts: 15,312

Threads: 530

Joined: Oct 2011

City: Jackson, NJ

Ron

It's permeable, plys open unfoiled end at the lower flange. It came out without much effort at all, plus the thinner did not make the paper warp.

Here it is.

People who do not drink, do not smoke, do not eat red meat will one day feel really stupid lying there and dying from nothing.

Posts: 15,312

Threads: 530

Joined: Oct 2011

City: Jackson, NJ

Received 0.0056uF caps to restuff 0.006uF Philco tubulars. These proved to be the most stubborn caps yet: I do not know what kind of compound this is they used for the plgs, but it doesn't melt. I broke the leads on one, and ended up crushing the p!ugs with a hammer, damaging one end so I had to trim the tube.

The second cap I approached differently: I held one lead in a vice and pulled the other lightly with pliers: after 5 minutes of heating the plug came out. The other end didn't fare as good: I ended up crushing this end too, though it worked better this time. Spent an hour for two caps, and I have another two of the same.

People who do not drink, do not smoke, do not eat red meat will one day feel really stupid lying there and dying from nothing.

Posts: 4,614

Threads: 51

Joined: Sep 2008

City: Sandwick, BC, CA

Mike;

I've run into tubular paper caps like those before, they were made by a company called "Good All" and had some sort of putty in them that does not melt with heat. "Good All" in spite of the name, does not have a good reputation, a guy who fixes TVs on You Tube calls them "Bad All" and he lives in an area where even paper Aerovox caps seem to be good after 60 years.

I never did try soaking them in lacquer thinner, but I don't really have any equipment that used "Good All" caps as OEM components, plus they are from the 1950s and therefore too new to bother with.

Regards

Arran

Posts: 15,312

Threads: 530

Joined: Oct 2011

City: Jackson, NJ

Arran

I take it, Philco might use re-labeled caps then? These are the only ones in the whole radio that behave like this.

There are different waxes, those brown that melt more readily and those greyish-brown or grey that melt not as good, but all do melt and come out without major problems. These are 6nF 450V caps and the only type I ever encountered using this type of putty or whatever that is.

People who do not drink, do not smoke, do not eat red meat will one day feel really stupid lying there and dying from nothing.

Posts: 4,614

Threads: 51

Joined: Sep 2008

City: Sandwick, BC, CA

Mike;

I don't think that Philco was making their own capacitors by this point, it seems like they were contracting this out to outside suppliers who would label the caps as Philco brand, with their part numbers, and so forth. I can remember taking one of those cap and choke assemblies apart in one of their transformerless sets from the 1940s and found a Sprague brand cap inside of the cardboard tube they used as a coil form, and clearly it left the factory this way. Whether Philco always used Sprague as an outside supplier I don't know, maybe by 1953 they were sourcing from whoever would supply what they wanted at a given moment, maybe "Good All" was one of them?

Regards

Arran

Posts: 15,312

Threads: 530

Joined: Oct 2011

City: Jackson, NJ

06-16-2018, 06:49 PM

06-16-2018, 06:49 PM

This is how the plugs from the caps look after extraction. They havent lost the shape in the least bit.

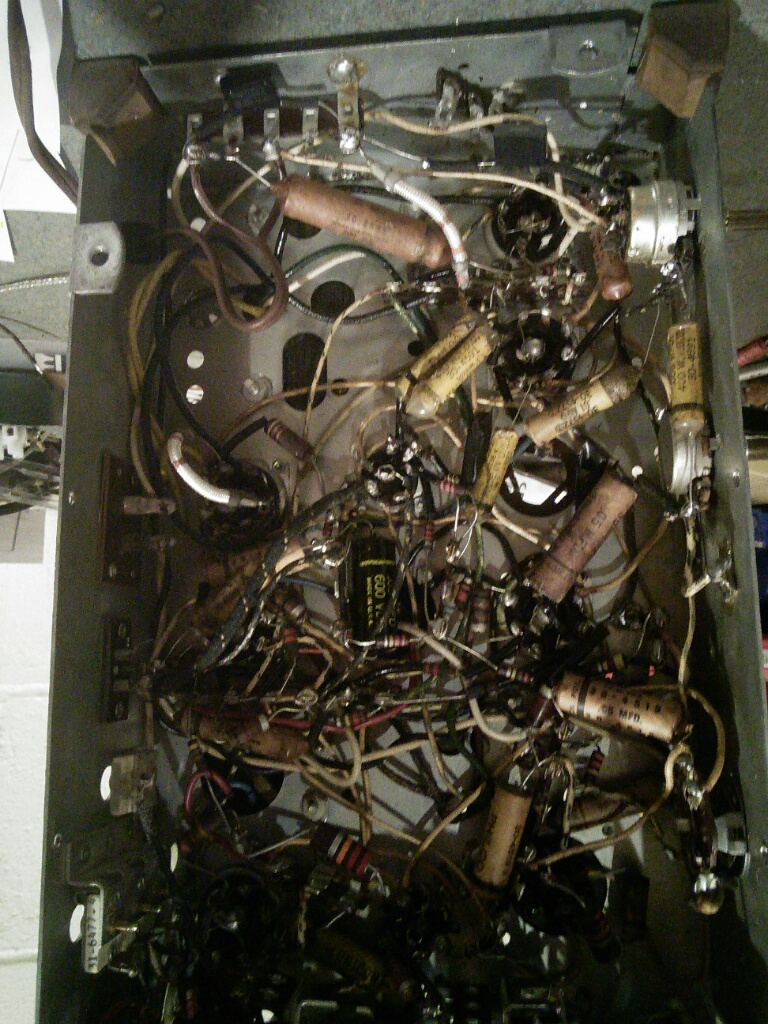

The chassis after tubulars recap.

People who do not drink, do not smoke, do not eat red meat will one day feel really stupid lying there and dying from nothing.

(This post was last modified: 06-16-2018, 06:56 PM by morzh.)

Posts: 15,312

Threads: 530

Joined: Oct 2011

City: Jackson, NJ

The twistlock cap. Being glued together. Will dry up tomorrow.

People who do not drink, do not smoke, do not eat red meat will one day feel really stupid lying there and dying from nothing.

Posts: 1,475

Threads: 69

Joined: Nov 2012

City: Kansas city, MO.

Good job Mike.  It should be a good playing radio when you're done.

Posts: 15,312

Threads: 530

Joined: Oct 2011

City: Jackson, NJ

One more twistlock and hopefully this will be it. This one also isn't in a cadboard shell so maybe it'll be easier. But I hate that phenolic panel they are mounted on.

People who do not drink, do not smoke, do not eat red meat will one day feel really stupid lying there and dying from nothing.

(This post was last modified: 06-17-2018, 06:49 PM by morzh.)

Users browsing this thread: 1 Guest(s)

|