Posts: 1,181

Threads: 48

Joined: Oct 2017

City: Allendale, MI

Posts: 189

Threads: 22

Joined: Aug 2018

City: Kewanee

State, Province, Country: Illinois

Nice! I'm a clock affectionado, due to the fact it is also a radio, just makes it that much better.

1929 Victor R-32, 1933 60L, Phil 40-158, Phil 42-400X, Phil 47-1230 Radio/Phono,, 1950 Phil TV t-1104, Air King 4000, Philco 41-105, Philco 37-675, RCA Victor 9K2, PT-50, Phil 54C, PT-44 Cabinet, Phil 118X Cabinet

Gregg

Posts: 1,824

Threads: 114

Joined: Jul 2014

City: Sneedville, TN

I'm viewing the site with my desktop. The pictures are fine with my setup. Very cool clock / radio combo ! Good luck with the restoration.

Posts: 816

Threads: 25

Joined: Mar 2014

City: Louisville, KY

(04-19-2019, 08:47 PM)rfeenstra Wrote: Edit: Ron, Nathan, or someone, why are my pics so big? The phorum used to scale them down. Do I need to change the # of pixels per inch?

Who's complaining?  They're gorgeous!

Jake

(This post was last modified: 04-19-2019, 10:48 PM by Jake Blake.)

Posts: 1,181

Threads: 48

Joined: Oct 2017

City: Allendale, MI

The radio is a bit of a basket case. Disassembly has begun. First problem I've found is the power transformer. Half the HV winding is open. I'll either have to rewind it or place an ad in the wanted section. This is the first PT problem I've run into (other than having to rewire because of rubber wire or brittle cloth wire.

Since the coil shields are impossible to remove and re-install, re-plating this chassis has been ruled out. It will be painted.

Posts: 1,856

Threads: 212

Joined: May 2015

City: Seattle

State, Province, Country: WA

The pictures should scale to the size of your browser width now. We also upped the limit on Mac picture size considerably based on feedback.

Your pictures look good on mobile. On desktop you should be able to resize the width of the browser. I suppose we could also set an absolute maximum width.

Posts: 1,181

Threads: 48

Joined: Oct 2017

City: Allendale, MI

Thanks for the info, Nathan.

Posts: 1,181

Threads: 48

Joined: Oct 2017

City: Allendale, MI

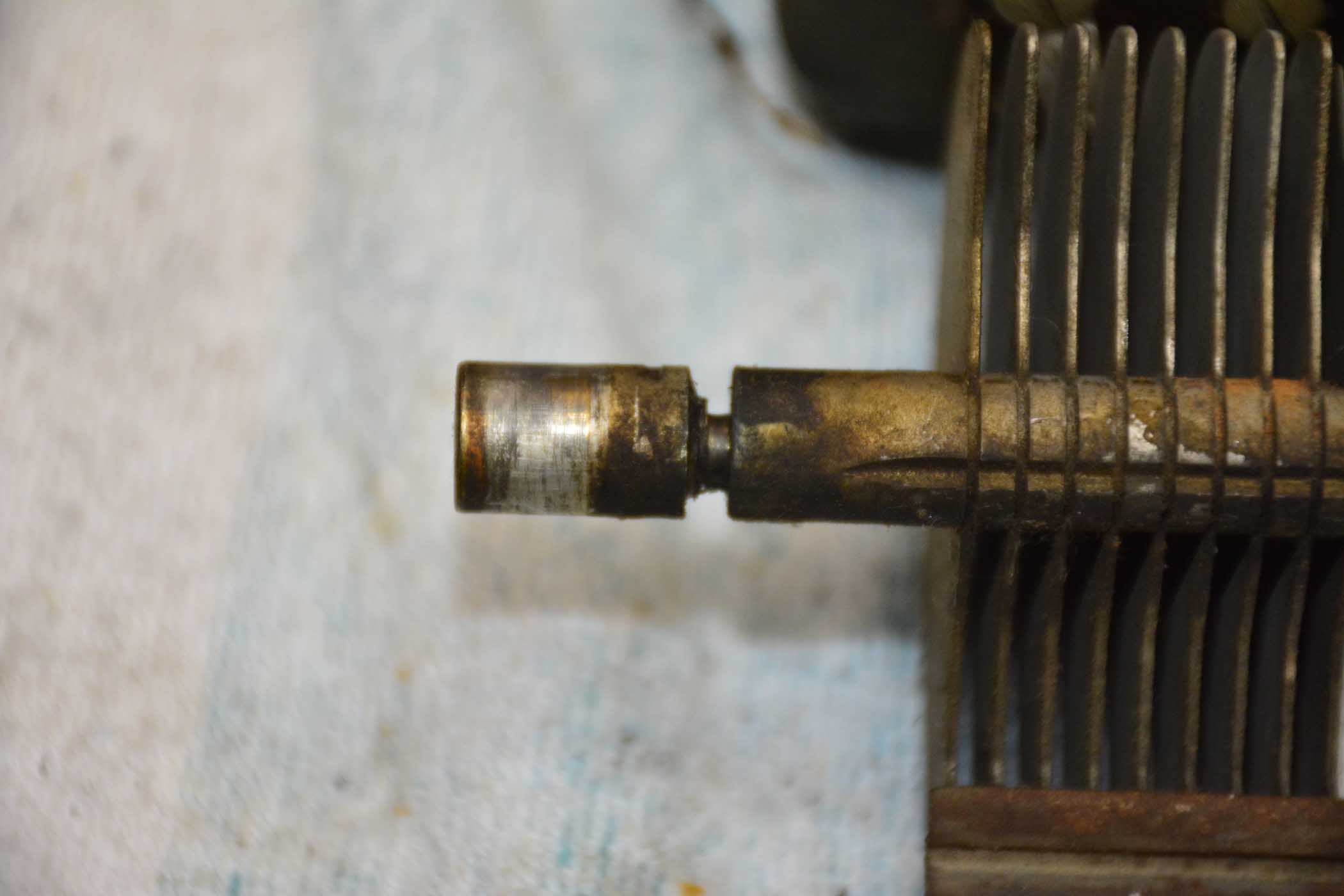

This radio was certainly well used. The tuning shaft is deeply worn at the bearing support, and the dial drive surface is worn to a knife edge. Not quite sure how I'm going to address the issues, but I have some ideas.

Edit: Because of the wear on the dial, someone tried to bend and otherwise mangle the piece to increase the friction on the drive. I've tried to straighten it as best I can. Now I have to add some metal to the worn edge to get it back to some semblance of original dimensions.

(This post was last modified: 04-20-2019, 09:54 AM by rfeenstra.)

Posts: 1,181

Threads: 48

Joined: Oct 2017

City: Allendale, MI

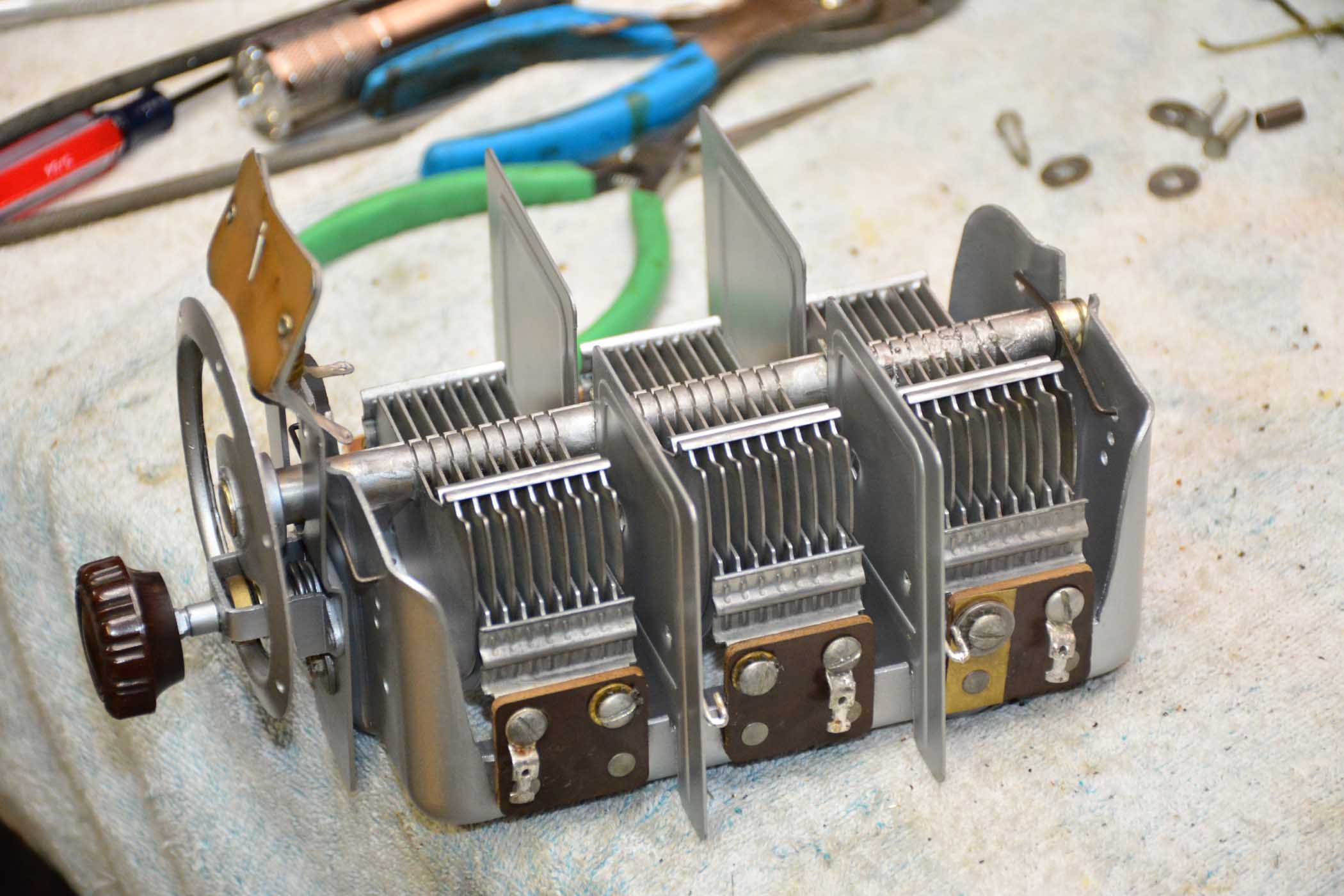

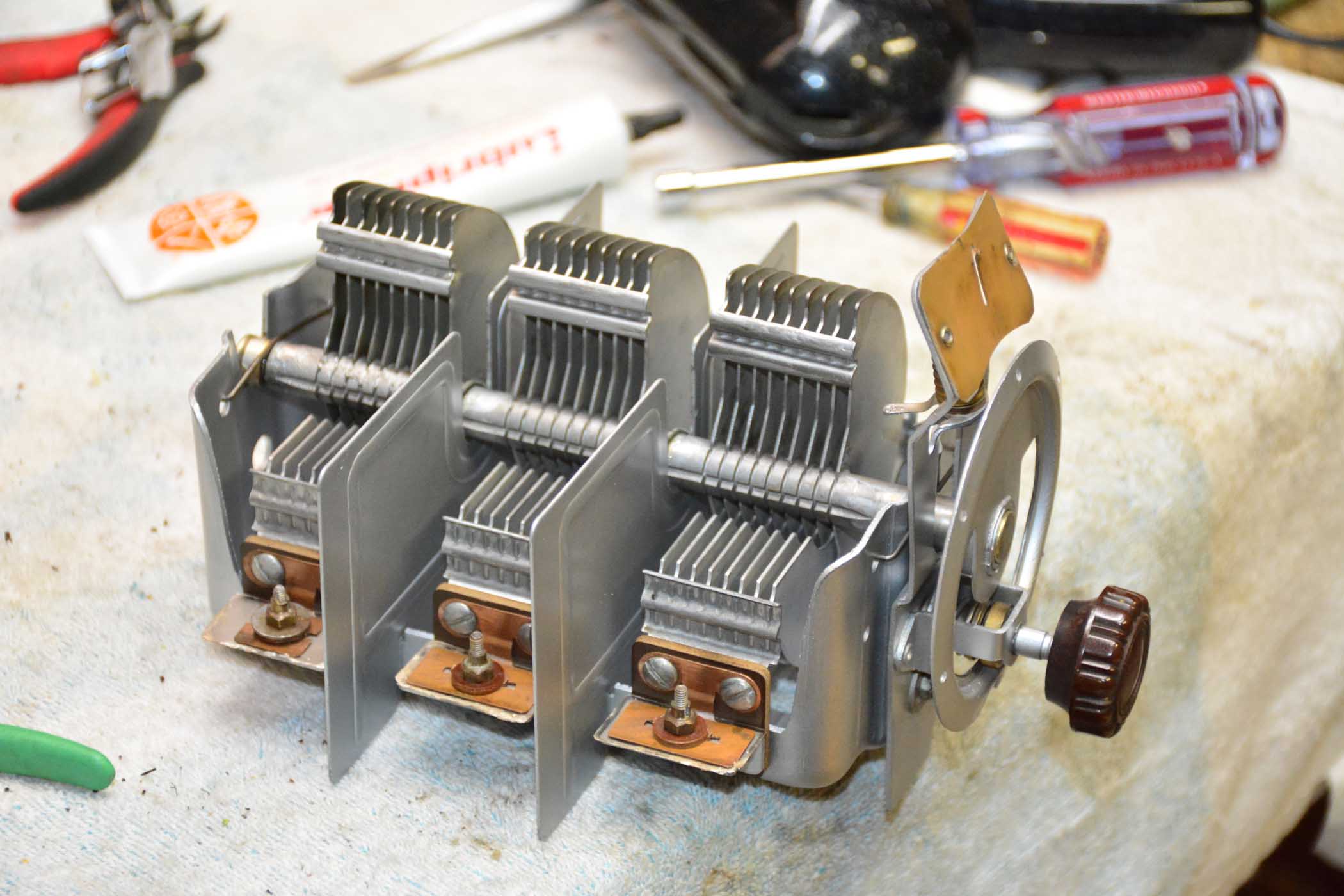

Decided to start on the tuner. Was able to fill in the groove on one end of the shaft by brazing it. I didn't fill the groove left by the retainer spring. That gets closer to the plates. That takes a lot of heat and I had a hard time keeping the solder on the nearest plates from melting. You can see some roughness in the solder where it started to flow. After brazing the groove, I turned it down on the lathe. There was no way I was going to be able to braze the tuning knob end as the normal groove is deep. I filled that with silver solder and turned it down in the lathe. I don't know how long the silver solder will hold up, but it's better than it was.

I carefully sanded the knife edge off with a dremel tool. I tried to straighten the edge as best I could from the former "repairs". Thankfully, I didn't have to add any metal. The spring loaded friction wheel still worked on the new edge. It's not perfectly smooth because I couldn't get all of the bends out of the metal. Pretty good, though. I'm pleased it works as well as it does.

Oh, and yes, it is painted so that it will match the chassis as that will have to be painted because of all the rust.

(This post was last modified: 04-20-2019, 10:42 PM by rfeenstra.)

Posts: 1,475

Threads: 69

Joined: Nov 2012

City: Kansas city, MO.

Very nice work on the tuning cap.

Posts: 1,181

Threads: 48

Joined: Oct 2017

City: Allendale, MI

Hmmm. Decided to start on the PT. Half of the HV secondary was open. Now that it's apart, it measures fine. I don't trust it, but hate to rewind it! I've wiggled the wires, tugged on them, pushed on them and I can't get it to open. Not sure what I'm going to do.

Posts: 1,181

Threads: 48

Joined: Oct 2017

City: Allendale, MI

Decision taken: it will be re-wound. Wire is on order and the PT is in process of being unwound.

Posts: 816

Threads: 25

Joined: Mar 2014

City: Louisville, KY

(04-19-2019, 10:58 PM)rfeenstra Wrote: The radio is a bit of a basket case. Disassembly has begun. First problem I've found is the power transformer. Half the HV winding is open. I'll either have to rewind it or place an ad in the wanted section. This is the first PT problem I've run into (other than having to rewire because of rubber wire or brittle cloth wire.

Since the coil shields are impossible to remove and re-install, re-plating this chassis has been ruled out. It will be painted.

(04-22-2019, 11:26 AM)rfeenstra Wrote: Decision taken: it will be re-wound. Wire is on order and the PT is in process of being unwound.

You mean you're not mining your own copper???!!!

I'm gonna keep shopping on Ebay for mine. I've already had some referrals from Terry.

Posts: 1,181

Threads: 48

Joined: Oct 2017

City: Allendale, MI

I was thinking about it since I live only 9 hrs form old copper mines, but I don't have the dies to draw out the wire!

Posts: 816

Threads: 25

Joined: Mar 2014

City: Louisville, KY

(04-22-2019, 04:22 PM)rfeenstra Wrote: I was thinking about it since I live only 9 hrs form old copper mines, but I don't have the dies to draw out the wire!

HA!!!!! Ok bud. I'm sure if you are sucessful with that re-winding, that will be the nicer restoration.

Users browsing this thread: 1 Guest(s)

|