Posts: 13,776

Threads: 580

Joined: Sep 2005

City: Ferdinand

State, Province, Country: Indiana

Forgot to mention:

Rebuilding a tone control is no harder than rebuilding a Bakelite block. It involves removing the capacitors, which are encased in a hard waxy substance, and wrapped with thin fiber which has the electrical characteristics of fishpaper (i.e. an insulating material).

I like to reuse the fiber material after getting rid of the old capacitor assembly, to ensure the new caps are insulated from the metal case.

Of course, there is more to rebuilding a tone control than this. I'm afraid I don't have time to explain fully at the moment. Anyone else, feel free to chime in.

--

Ron Ramirez

Ferdinand IN

Posts: 45

Threads: 6

Joined: Apr 2023

City: Temecula

State, Province, Country: CA

And indeed, tearing it apart reveals all three. At least the wax is contained in a paper "box" inside the metal box... much easier to dig out.

As a newbie, I don't have bins full of caps, and I had JUST received all the other caps I needed from Just Radios... I thought. Now I find these three and I have to place another order! 15 years ago I had a store just down the street that had aisles full of these goodies (not a Shack)... nowadays I get to pay postage.

Posts: 1,436

Threads: 88

Joined: May 2008

City: Omak

State, Province, Country: WA

Hello Pat,

Yes,I know where you are coming from with the local parts houses one my favorite was my local radioshack everything from from raw speakers to project boxes .

The tone control is not to bad to do if you have done Bakelite blocks the tone control is a breeze .

Sincerely Richard

Posts: 45

Threads: 6

Joined: Apr 2023

City: Temecula

State, Province, Country: CA

Replaced almost all my resistors... almost every one was either open or way off (3x 1Meg were ~1.7M, 2M, 2.5M). the big 2W 32k beast was spot on, think I'll keep it as a link to the past. Still wondering how this radio worked at all.

Saw an article elsewhere on making "repro" resistors, painted up just like the originals. Very tempted even though no one would see them!

Posts: 45

Threads: 6

Joined: Apr 2023

City: Temecula

State, Province, Country: CA

Somewhere above I was wondering why my filament circuit halves seemed to be connected to each other AND to ground. Those in the know were polite and made no mockery of the noob- thanks!

Found that: a) The 6A7 socket has a hidden little tab that connects filament (pin 7) to the mounting rivet- and ground.

And b): Of course the transformer secondary for the filaments connects the two sides together with almost zero resistance...duh.

Remember, I'm a MECHANICAL engineer... they did tell me not to stick my fingers inside the electronics boxes...

Achtung! Alles Lookenspeepers!

Das computermaschine ist nicht für gefingerpoken und mittengrabben. Ist easy schnappen der springenwerk, blowenfusen und poppencorken mit spitzensparken. Ist nicht für gewerken bei das dummkopfen. Das rubbernecken sightseeren keepen das cottenpickenen hans in das pockets muss; relaxen und watchen das blinkenlichten.

Posts: 45

Threads: 6

Joined: Apr 2023

City: Temecula

State, Province, Country: CA

Bouncing Tuners & Flexy Ground Straps

I've poked around with Searches and not found anything definitive on this, so I'll ask here.

My 655's tuner assembly is on soft rubber mounts, presumably for some sort of vibration isolation reason. But really? Why does a tuner need a soft mount?

BTW, tuning anti-vibration mounts for the desired effect is a whole science in itself, and it has to take into account the input vibration (ground motion), the mass and natural frequencies of protected parts, and the stiffness of the mounts. I wonder if these are just off-the-shelf mounts thrown in there just because of some suspicion that they might do something useful?

And regarding the three braided ground straps connecting tuner frame to chassis: There ain't nuthin magical, electrical, RF-ish or Litz-ish about that braid. Just like the ground strap from your car's engine to body, a braid is only used because it can take the flexing that comes from the ends' relative motion without breaking or transmitting mechanical vibration between the connected parts.

Change my mind.

But again- why does the tuner need to move in the first place?

OK, I'll throw out one guess: The mounts don't isolate vibration... instead they allow for thermal expansion of the chassis without stressing the presumably cooler and delicate tuner frame.

In that case, why not achieve grounding via simple looped solid wire? Or even simple stranded wire? Why all the grief of these braids?

Posts: 15,311

Threads: 530

Joined: Oct 2011

City: Jackson, NJ

I usually make the new inner lining from fishpaper, as the old one does not necessarily survives, plus the new caps, unlike the old ones, have leads that can touch through the seams before potting....I would prefer the old one, but it is not always possible for me.

PS. I posted several radios threads that required tone ctl rebuilding, and every time when potting, I create a little dome from the same fishpaper over the caps' bodies. I do not fully enclose them, but make it enough to prevent massive quantity of molten plastic from enveloping the caps, to prevent a possible cap damage by the temperature. There will be enough hot glue to still go in a bit and to stabilize the bodies, and it will coat leads and wires to keep everything sealed and insulated.

People who do not drink, do not smoke, do not eat red meat will one day feel really stupid lying there and dying from nothing.

(This post was last modified: 04-30-2023, 01:16 PM by morzh.)

Posts: 838

Threads: 36

Joined: Feb 2015

City: Roseville, MN

Pat, the reason for the tuner ground straps is two fold. One is to provide a solid ground for the tuner frame. Mechanical connections just don't provide enough reliable electrical connection for an RF path. So, they do prevent microphonics from occurring. The second is that, now you have a tuner frame mechanically isolated from the chassis, the braid is plenty flexible to contend with vibration, especially aircraft, ships, tanks, etc. There is a third that hasn't been proven; many designers have, back in the day, invested in companies that manufactured high wattage soldering irons.

IMHO 3 straps is overkill. One should be sufficient.

Posts: 45

Threads: 6

Joined: Apr 2023

City: Temecula

State, Province, Country: CA

Thanks, I may take my chances with simplified ground wires in place of those $#@$! braids.

Today's puzzler: What the Heck?!

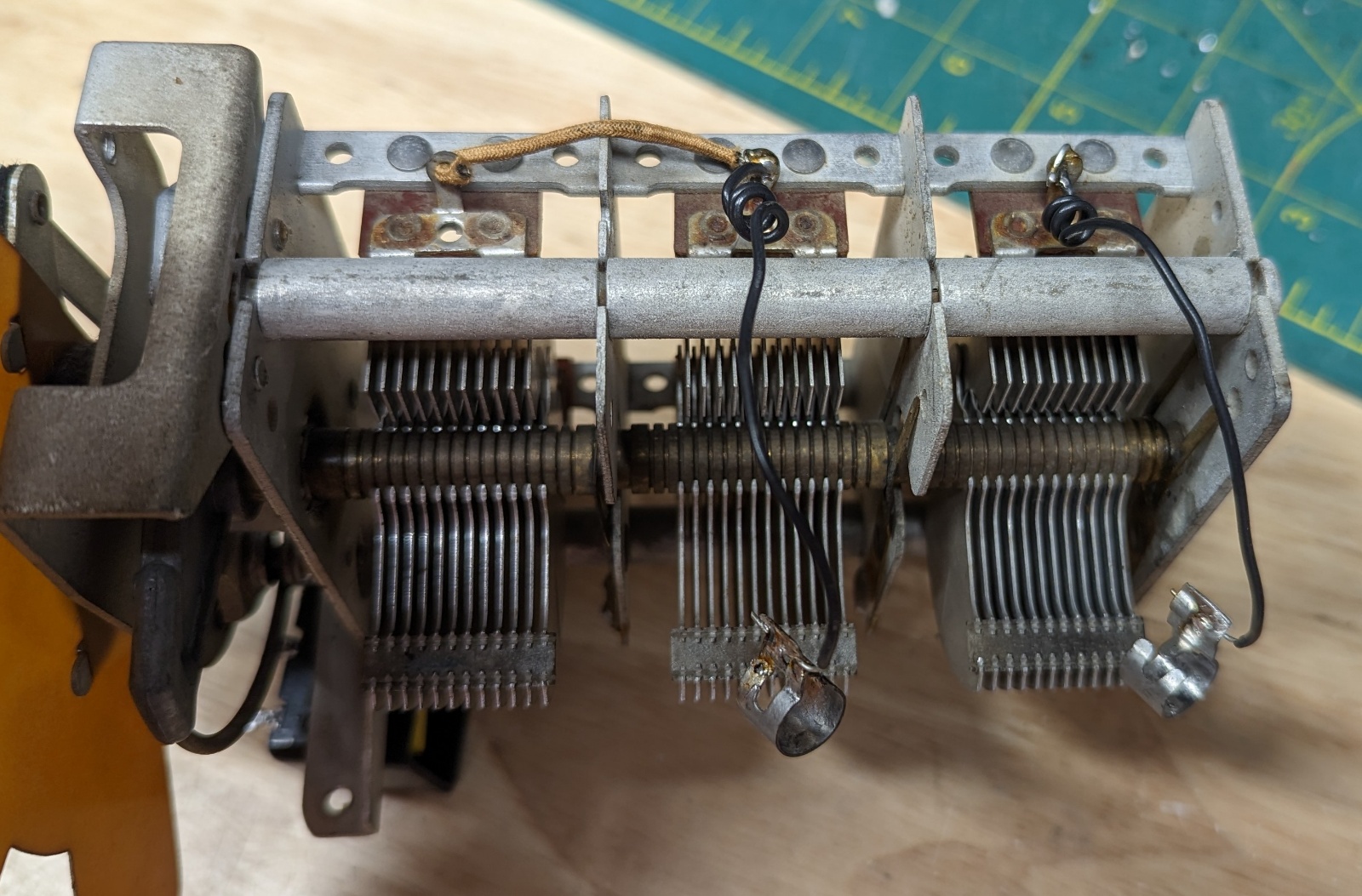

Here's my cleaned up tuner assembly. Two gangs have leads to the caps of the 78 and 6A7 tubes.

But then there's that little tan (was white?) wire between the mid and front gangs. Hmmm...

And at the front gang- the wire is merely looped through the lug- no solder, and that lug has NEVER had solder. It's clean.

Those two gangs are not supposed to be connected at all. The first gang should be connected to Grid 0 (pin 5) on the 6A7, and to some lug on the band switch that I haven't traced yet.

Any ideas?

Posts: 7,215

Threads: 266

Joined: Dec 2009

City: Roslyn Pa

It's a gimmick capacitor that couples some of the osc signal into the input of the mixer.

When my pals were reading comic books

I was down in the basement in my dad's

workshop. Perusing his Sam's Photofoacts

Vol 1-50 admiring the old set and trying to

figure out what all those squiggly meant.

Circa 1966

Now I think I've got!

Terry

Posts: 13,776

Threads: 580

Joined: Sep 2005

City: Ferdinand

State, Province, Country: Indiana

+1 what Terry (RadioRoslyn) said.

Leave it alone. Do not bother it, modify it, remove it or attempt to solder it.

--

Ron Ramirez

Ferdinand IN

Posts: 13,776

Threads: 580

Joined: Sep 2005

City: Ferdinand

State, Province, Country: Indiana

RodB has given an excellent description of the reason manufacturers used flexible braided wire to ground tuning condensers and I agree with his analysis. Just keep the darn things; don't replace them with solid wires.

I'll only add this regarding the rubber grommets used to mount tuning condensers - they were intended to minimize vibration, with the close proximity of the radio chassis to the speaker - especially in cathedral, tombstone, and table model radios.

--

Ron Ramirez

Ferdinand IN

Posts: 45

Threads: 6

Joined: Apr 2023

City: Temecula

State, Province, Country: CA

Posts: 45

Threads: 6

Joined: Apr 2023

City: Temecula

State, Province, Country: CA

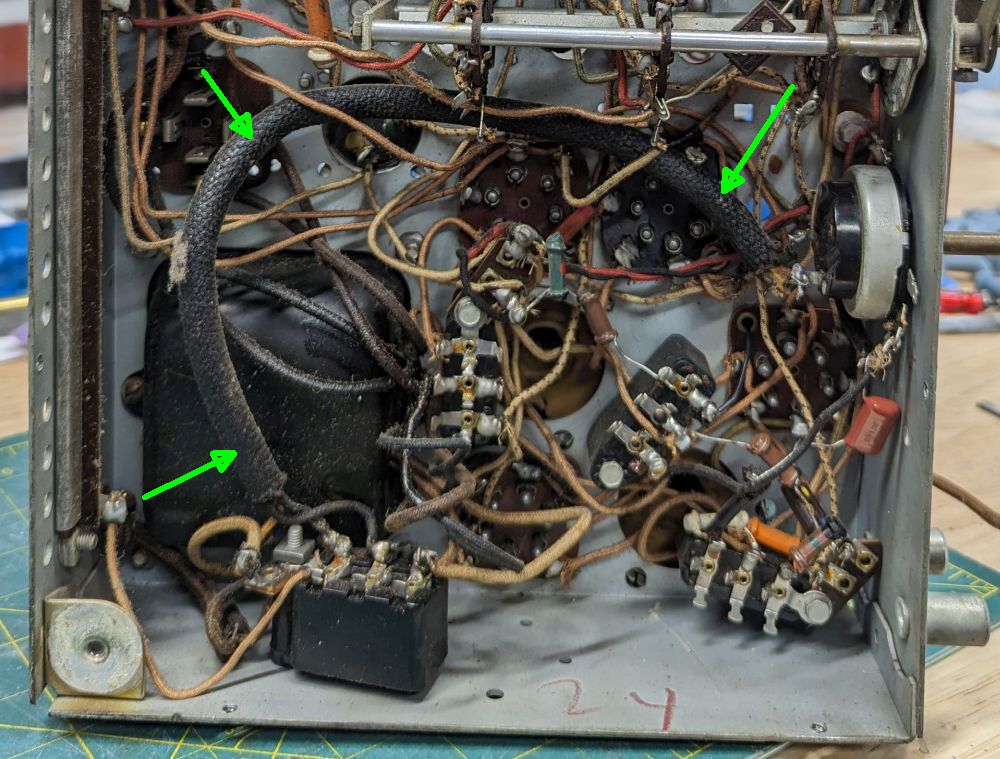

Shielded Power Cable:

I asked about this before, and the consensus is that the shielded power cable that crosses under my chassis is shielded for a reason.

OK, but it's nasty. All crackly and cracked rubber insulation. At least there's enough length where I can trim the ends a bit if that helps.

But if I want to replace it- with what? All the old power cables in my Old Cable Box that have shielding are foil-shielded. How to terminate THAT?

Proper braided shield 1-pair 18g cable is available... but I can't find it in less than 25 foot length at $5 a foot. Nope.

Posts: 13,776

Threads: 580

Joined: Sep 2005

City: Ferdinand

State, Province, Country: Indiana

A cut length of shielded twin pair cable from eBay would probably be your most economical choice. It needs to be 18 gauge and rated at least 300V. Here's the cheapest one I found in a brief search:

https://www.ebay.com/itm/255115465280 - 25 feet, 18 AWG, 300V - $6.95 plus shipping and tax

And that's $6.95 for the entire 25-foot length, not $6.95 a foot.

That's a great deal. This cable if purchased new is very expensive. I also looked at Mouser Electronics, and they only sell it in large rolls which run from the hundreds to the thousands of dollars.

--

Ron Ramirez

Ferdinand IN

Users browsing this thread: 1 Guest(s)

|