Cleaning Tuning Capacitor

Posts: 348

Threads: 48

Joined: Oct 2013

City: Tioga, Texas, USA

The 40-201 chassis has a 2-gang tuning capacitor that needs cleaning. I have seen several illustrations of before and after units that look like new after cleaning. What process is used?  I am thinking that perhaps using an ultrasonic bath would do the trick. One area that needs extra caution is the bearings in these units. Lubrication definitely needs to be added after cleaning before rotating the parts.

Joe

(This post was last modified: 11-24-2013, 10:35 AM by Joeztech.)

Posts: 2,128

Threads: 18

Joined: Oct 2008

City: Merrick, Long Island, NY

Lots of information has already been posted, and of course opinoins vary (no pun intended.)

If it is not too filfthy, open all the way, spray with tuner cleaner or deoxit, brush softly spray again, catch fallings with a paper towel, let dry overnight, and yes, oil the bearings/bushings with a toothpick of lithium grease, followed by a toothpick tiny drop of WD40, and you're all set. ANy rmaining dust can usually be cleared by a piece of paper between rotor and stator blades. If the paper sticks, that means the blade is stuck and the part will not work.

Have not heard any good things about ultrasonics for this purpose, but could be called for in certain situations. Dunno.

Posts: 2,118

Threads: 112

Joined: Jun 2010

City: Medford OR (OR what?)

I would try the ultrasonic cleaner. if I had one. Let us know how it works.

Don't use any cleaner that might react with aluminum.

"I just might turn into smoke, but I feel fine"

http://www.russoldradios.com/

Posts: 348

Threads: 48

Joined: Oct 2013

City: Tioga, Texas, USA

OK guys, thanks. I do not have an ultrasonic cleaner, but I think I could find one. So far all I have done is to brush off surface dust using a soft camel hair brush and added some lubrication before I turned the tuning capacitor to facilitate additional cleaning. None of the vanes appear to be touching - movement is nice and smooth. I removed the capacitor and its mounting bracket plus dial-cord pulley from the chassis, so at least I will be able to get to all sides of it.

I think it best to avoid Formula 409 or anything with ammonia or chlorine. I know that chlorine will corrode aluminum over time.

Joe

Posts: 15,306

Threads: 531

Joined: Oct 2011

City: Jackson, NJ

Well, I cleaned all my capacitors either with dish soap and hot water, soaking it first and then using liong soft brush (although as the experience showed me, brush was not necessary - running water took care of everything after soaking), or, in case of old big ones, like from Philco 20, dishwasher cycle with cascade took care of it also well. It will not be sparking after that but a little dulling does not affect performance.

Dry thoroughly after that which is simply done by blowing the excess water with compressed canned air, and then leaving on a paper towel overnight at regular room temperature. In my recent posting about Stromberg-Carlson you can see the cap after that cleaning, and the blades came out very nice. The rods were darker but this is patina which could not be simply washed off and I am unwilling to subject a tuning cap, it being a rather delicare creature, to a harsh mechanical treatment.

In any case, even if you decided that you do not want any sparkle there, simply blowing the dust out with compressed air (not too strong, could bend the blades otherwise) will render it fully operational.

Posts: 348

Threads: 48

Joined: Oct 2013

City: Tioga, Texas, USA

Morzh;

Yes, I do understand about not using too strong a force of air when dealing with tuning capacitors. I read in another thread that some people have damaged the trimmer mica of the trimmer capacitors by using too much air force. Your experience shows that plain detergent and water is a good cleaner as with most items. Since I have already removed it from the chassis, this should not be too difficult to do.

I did speak with my youngest son and found out that he has an ultrasonic cleaner. The only precaution is that there is a plastic bowl that has to be used when cleaning items in it in order to not damage the metal sink in the cleaner. Due to the tiny rapid vibrations, any metal object that comes into contact with the metal sink of the cleaner can cause erosion of its metal and then corrosion will set in and eventually destroy the ultrasonic cleaner. Now that I know how to use it, I may give the water and detergent approach a try. We have well water which includes a rather high salt content plus other minerals and we treat our water with chlorine for sanitation. For cleaning the tuning capacitor, I may substitute some distilled water since it has no contaminants in it just to be safe.

Thanks for your input.

Joe

Posts: 335

Threads: 50

Joined: Apr 2011

City: Apple Creek

State, Province, Country: Ohio

I use my ultrasonic cleaner from Harbor Freight. I use warm water with dawn and hit it with a few cycles with the heater on. Cleans them up really well. Blow dry with about 15-20psi of compressed air and let it sit a few days to dry completely. Make sure to re-grease the bearings and lube the shaft.

Video with it in action cleaning the dials from my Mystery Control: [Video: http://youtu.be/ZerlGVzZg6U]

Posts: 348

Threads: 48

Joined: Oct 2013

City: Tioga, Texas, USA

Keith;

Great video. Looks like two minutes is sufficient, so I will give it a try. Warm water would make any action work better. We have some Dawn detergent on hand. I will take some before and after pictures.

Thanks.

Joe

Posts: 348

Threads: 48

Joined: Oct 2013

City: Tioga, Texas, USA

It turned out that the ultrasonic cleaner my son had was defective due to vinegar getting on the internal circuit board and corroding it very bad. Parts came loose and it went phffffft when I plugged it into the AC socket. I went ahead and used some hot distilled water and some detergent and soft brush to clean. I am not too happy with the results, but it does look better. I may get a replacement ultrasonic cleaner, as we often have a need for such an item.

I have a question about the rubber grommets on the mounting studs of the ganged tuning capacitor. They cushion the mounting of the condenser, probably to prevent microphonic feedback. The ones on this unit are cracking. I think the GPH-RFTR grommets shown on Renovate Radios website are the correct ones. Can someone confirm?

Joe

Posts: 348

Threads: 48

Joined: Oct 2013

City: Tioga, Texas, USA

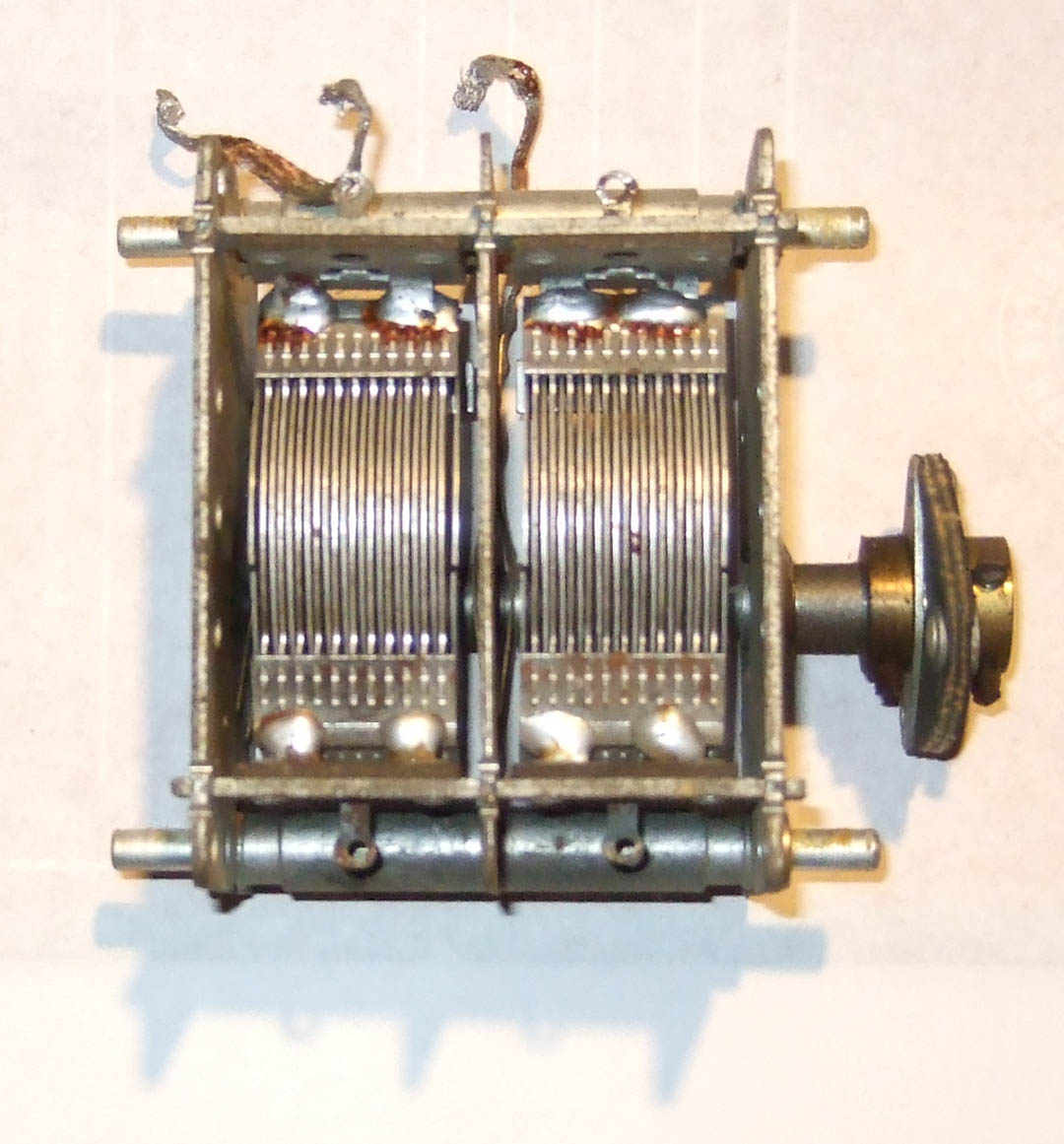

Yesterday I cleaned the tuning capacitor. This is the result.

Posts: 15,306

Threads: 531

Joined: Oct 2011

City: Jackson, NJ

Well, good result, clean cap. Solder it back now.

Posts: 348

Threads: 48

Joined: Oct 2013

City: Tioga, Texas, USA

morzh;

ipwizard had a good video of using his ultrasonic cleaner. Unfortunately when I tried to use my son's unit, it shorted out. It was the same brand and model as ipwizard's unit. It turned out that when my son used his with a vinegar solution, some of it splashed to the top of the metal bin or sink in the unit and ran up over the edge and fell down on the circuit boards. It corroded the board to the point that some of the parts were floating around loose.

On this capacitor I used a hot water and detergent solution, plus on the external parts I finally resorted to using a pink pearl eraser to remove some stubborn corrosion. It looks pretty good now. Mechanically it moves smoothly after re-lubrication with a small amount of 3-In-1 oil and lithium grease. The oil served to help liquify the lithium grease and get it down into the bearings.

I will re-install the capacitor as soon as I get the chassis repainted. It had significant corrosion on the top due to mice making a nest under the push-button control assembly and directly in front of the tuning capacitor. It was a really nasty mess.

Joe

(This post was last modified: 11-29-2013, 06:34 AM by Joeztech.)

Posts: 15,306

Threads: 531

Joined: Oct 2011

City: Jackson, NJ

yes, mice are known to not keep a tidy house, and to not use an outhouse even when one is available.

That's why we don't like them mousses. And ratses. And even spiders....though I like'em but when cleaning radios I have to kick the out, I don'wqant all the dead flies inside......

Speaking of rubber erasers, pinki or pearl or not - be careful with them as they, as every vulcanized rubber, have sulfur which is known to blacken silver, so if you have a silver wire or contact, do not clean it with rubber.

(This post was last modified: 11-29-2013, 07:01 PM by morzh.)

Posts: 348

Threads: 48

Joined: Oct 2013

City: Tioga, Texas, USA

morzh;

Yes I hate mice. They are nasty, filthy creatures that destroy everything around them. I found numerous spider webs and egg cases inside too. They all have to go!

Thanks for the information about the pink pearl eraser. There is another more modern type eraser that I often use which is an off-white almost gray color. It was originally created for artist work. One nice thing about this type is that it does not turn black when erasing pencil marks from paper. It is much more durable too and does not wear away as badly as a pink pearl eraser. I have never tried to use either type on switches since switch contacts are so delicate and extreme care needs to be used when cleaning them.

Now where did I misplace that screw!

Joe

Users browsing this thread: 1 Guest(s)

|

I am thinking that perhaps using an ultrasonic bath would do the trick. One area that needs extra caution is the bearings in these units. Lubrication definitely needs to be added after cleaning before rotating the parts.

I am thinking that perhaps using an ultrasonic bath would do the trick. One area that needs extra caution is the bearings in these units. Lubrication definitely needs to be added after cleaning before rotating the parts.